Sonic & ultrasonic generators

Sonic & ultrasonic transducers are electro-mechanical or electro-acoustic converters. They transform electric energy into vibrations, which are used to generate mechanical, acoustic or even thermal power. Sonic transducers operate at audible frequencies, while ultrasounds operate at 20kHz or above. Transducers are often reciprocal devices: Most transducers can operate as sensors or generators exploiting mecano-electric conversion. This section introduces only actuation or emission modes. Conversion in such transducers is generally based on piezoelectric, magnetostrictive or magnetic forces.

The most conventional approach consists in using such forces to excite a mechanical resonance. For the same electric excitation, the vibration at resonance is the low frequency vibration multiplied by the mechanical Quality factor at resonance. This allows to achieve a good efficiency and reduced excitation voltages. The alternative way is to generate forced vibrations. Forced vibrations lead to large frequency bandwidth and are much less sensitive to load variations.

The usual ultrasonic transducers also called industrial ultrasonic processors are resonant structures typically based on 3 half-wave length resonators : a piezo converter, a booster and a sonotrode. They are used for ultrasonic welding, milling, cleaning, nebulization or ultrasonic assistance in drilling, extrusion, homogeneisation, filter declogging… CEDRAT TECHNOLOGIES can define solutions using standard transducers. Customisation is often required to adapt the sonotrode to the load as shown below.

A new approach consists in using new active materials such as multilayer piezo ceramics (MLA) or giant magnetostrictive materials (GMM). These are used to build low frequency resonant transducers in dual-mass Tonpilz structures. Based on pre-stressed MLA, CEDRAT TECHNOLOGIES’s PPAs and APA® are relevant sources for ultra-compact resonant transducers because they offer very large dynamic strains (more than 1%) at low voltage (<10V) as in the Water Tracker. In addition, PPAs and APA® offer large strains outside resonance, what allows them to be used for forced vibrations, for example in tribometers, piezo shakers or various vibration assisted processes (glass / metal / composite cutting, drilling, edm …).

Eventually, magnetic actuators can be considered for low frequencies acoustic sources: CEDRAT TECHNOLOGIES MICAs magnetic actuators offer an interesting alternative to voice coils for higher forces density and for 10 times less heating. Giant Magnetostrictive materials (GMM) are an alternative to piezos for low frequency high power transducers (sonar).

Some examples are given hereafter or in our related publicationson sonic or ultrasonic transducers.

SONO“R”US : Machine for Microparts Moulding based on UltraSound Excitation

The aim of SONO“R”US is to allow redefining some of the key features of the prototype developed under the Sonoplast project. The result will be a ready-to-market micromoulding machine that represents flexible, reliable and cost efficiency solutions for producing complex shaped and functional parts.

Applications

Ultrasonic transducer ; Piezoelectric ; Magnetostrictive ;Micro injection, moulding machine, polymere, micro-part, European FP7 project

STATUS

Concept

SONO : A pilot line of antibacterial medical textiles based on a sonochemical process

The SONO project aims at developing a pilot line of antibacterial and antifungal medical textiles based on a sonochemical process patented at BIU laboratories. CEDRAT TECHNOLOGIES will develop the mechatronic hardware for this pilot line including the transducers.

Applications

Ultrasonic transducer ; Piezoelectric ; Magnetostrictive ; Sonochemical reactor ; medical textile

STATUS

Prototype

MUST: Modular Ultrasonic Transducer (developed in the frame of SONO Project)

The modular ultrasonic transducer (MUST) developed by CTEC improves the potential of classical tubular transducer. The main advantages:

-Longer sonotrode with up to 5 meters length – Bigger surface of cavitation

-Uniformity of the treatment improved -Better efficiency of the electro-acoustic conversion.

Applications

Ultrasonic transducer ; Piezoelectric ; Magnetostrictive ; Sonochemical reactor ; medical fabrics

STATUS

Prototype

Sonic & Ultrasonic assistance in machining and production process

In machining, cutting or drilling operation, vibrations reduce the friction rate between bodies in relative motion. Piezo actuators or transducers operating either in forced or ultrasonic resonant mode can improve the process speed and quality.

Applications

Machine tool, cutting, drilling, milling ; improvement of quality and speed process

STATUS

Prototype

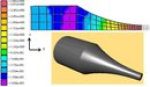

Ultrasonic Transducers Modelling & Design & Prototyping

For applications requiring high ultrasonic power, standard solutions cannot be used directly. It is important to design the appropriate sonotrode to tune the transducer and the load. ATILA FEM can help in such design and to make working transducers.

Applications

Welding, cutting, homogenizing, emulsifying, ultrasonic cleaning, aerosol generation

STATUS

Prototype

Water Tracker long range low frequency sonic transducer

WATER TRACKER tracks and localizes urban water pipes using acoustic waves. The WATER TRACKER emitter is an APA®-based transducer operating at low frequency with high amplitude vibrations for long range sound emission.

Applications

Sound emission, High Power sonar Transducer, acoustic localization

STATUS

Product

SONOPLAST European project for ultrasonic assistance in micro-manufacturing

The goal of Sonoplast FP7 project is to develop an innovative process using ultrasound for polymere micro injections, in order to manufacture high precision micro-parts (<10gr). CEDRAT TECHNOLOGIES is in charge of ultrasonics.

Applications

Micro injection, molding machine, polymere, micro-part, European FP7 project

STATUS

Prototype