Publications

Categories

- (34)

- (9)

- (3)

- (143)

- (18)

- (7)

- (4)

- (8)

- (9)

- (17)

- (2)

- (104)

- (7)

- (14)

- (7)

- (1)

- (1)

- (6)

- (155)

- (20)

- (2)

- (5)

- (111)

- (35)

- (11)

- (4)

- (59)

- (18)

- (3)

- (7)

- (62)

- (18)

- (5)

- (24)

- (7)

- (12)

- (1)

- (2)

- (2)

- (1)

- (1)

- (14)

- (13)

- (4)

- (6)

Design of a dynamic tribometer applied to piezoelectric Inertia Drive Motors – In situ exploration of stick-slip principle

19 June 2023

In Inertia Drive Motors, generated motion is based on stick-slip principle. Current analytical models are predictive enough to calculate qualitatively their optimal performances, such as maximal step size and speed, with relatively few input parameters. But, they do not take into account the contact life and temporal evolution of parameters as friction factor all along lifetime of IDM. So, analytical models reach their limits when precise predictions are necessary. This investigation aims at understand wear mechanisms to model temporal evolution of friction. Such an understanding requires the reconstitution of the contact life through the evaluation of 1st and 3rd body flows. To do so, a new IDM-representative tribometer is designed. First bodies – coated TA6V and polymer – are not see-through. They are replaced alternatively by an intermediate transparent first body to observe the contact dynamically and in-situ. Friction factor, step size and mean speed are also measured. Preliminary results shows that wear profiles from real IDM and tribometer are similar. Direct observations bring out particles of TA6V coating are firstly snatched, then moves in contact and finally trigs others particle detachments.

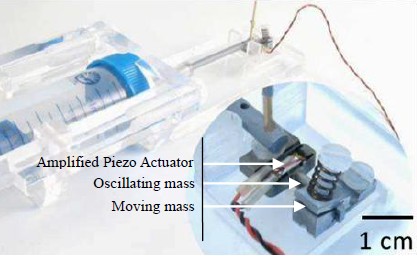

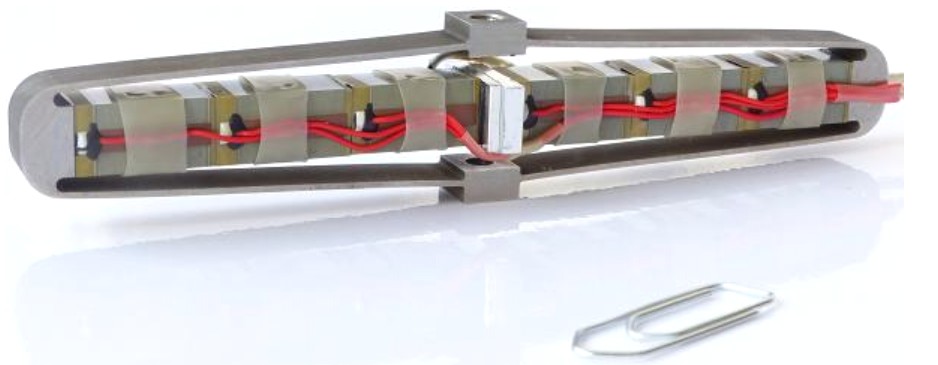

Benefits from amplification of piezo actuation in inertial stepping motors

19 June 2023

Stepping Piezo Actuators (SPA) are long stroke linear piezoelectric actuators capable to reach long stroke (typ. >10mm) with an important resolution (typ. <1nm). It has been proposed to use Amplified Piezo Actuator into inertial stepper motor to build the SPA. This piezo motor showed good behaviour, with relatively high speed (up to 70mm/s), force (from 0.2N to 20N) and low consumption (down to 700mW).

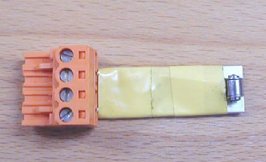

Bistable micro actuator for energy saving

19 June 2023

The article describes a linear magnetic flip-flop micro actuator, designed with FLUX software, assembled and characterised for a specific application requiring low losses at function states. The micro size allows reducing the energy required for actuation. Permanent magnets ensure bistability and suppress losses at functional states. Although the actuator is less than 1 g, the blocking force is about 0.1N and the stroke is 0.6mm. Firstly, the paper describes the main functionality of the actuator. Then are presented measured characteristics and results are compared with FLUX software computation. Finally perspectives of further miniaturisation are discussed.

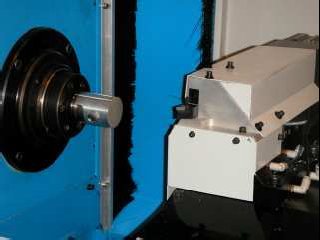

Actuators in adaptronics: piezoelectric actuators

19 June 2023

Piezoelectric actuators have increased their number of application in adaptronics over the past decade [1]. They can be used with several drive and control strategies and they are more adapted to mechatronics applications requiring bandwidth, accuracy and/or lightweightness. The purpose of this paper is to recall the different existing piezo actuators, the different drive and control techniques and finally review several applications in machine tools, optics.

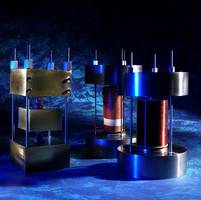

Actuators, transducers and motors based on giant magnetostrictive materials

19 June 2023

Rare earth-iron magnetostrictive alloys, especially Terfenol-D, feature “giant” magnetostrains: static strains of 1000-2000 ppm and dynamic strains of 3500 ppm are reported.

Advantages of large piezo actuators and high power drivers for fatigue and fretting test

19 June 2023

Constant expansion of new materials requires fretting or fatigue machines in order to test their failure. In many cases tests must be performed in severe conditions and at high frequency. These requirements come from the use of the materials in highly demanding applications. At the same time it is expected to reduce the time required to characterise such materials. Piezoelectric actuators are more and more common in testing machines, but they still reach limitations in terms of maximum displacement, cycling frequency or power. In order to cope with these issues, Cedrat Technologies has been investigating solutions. In this paper long stroke and high frequency actuators, coupled with powerful driving control are introduced. These actuators are based on piezoelectric materials and can be easily integrated into the fatigue machines. In order to improve precision of these tests, two of the most common displacement sensors used in smart actuators are also presented in this paper.