Applications for electro-optical and laser systems

CEDRAT TECHNOLOGIES (CTEC) designs, manufactures and continuously improves high-performance mechatronic products for the defense market. Our portfolio includes Fast Steering Mirrors (FSM), XY positioning stages and compact controllers engineered to operate in harsh environments.

These solutions are used in demanding applications such as Line of Sight Stabilization for beam wander cancellation of High Energy Laser (HEL/DEW) as well as for improving Narrow Field of View image quality of Electro Optic Systems (EOS), microscanning and dithering (pixel shift) function for image resolution enhancement (super-resolution imaging) of camera, back scanning for anti-blurring image processing.

To meet specific customer requirements, CTEC also develops piezoelectric and magnetic mechanisms with dedicated embedded electronics and mirrors on demand.

What are electro-optical and laser systems used for?

Micro-scanning, Dithering

or Pixel shifting

Micro-scanning, Dithering or Pixel shifting is a technique which increases the true resolution of a detector (CCD, CMOS, FPA, etc…) by moving a focal lens or the detector itself by fractions of a pixel in the x- and y-directions. The main customer benefit is to enhance the resolution of their existing detector at a much lower cost than buying a twice higher resolution detector. Depending on the optical configuration and the detector type of the customer camera or electro optic system, CTEC can develop either embedded XY or Tip Tilt stages with their related controllers to move respectively a focal lens, a detector or a mirror.

Image Stabilisation for High-Resolution Electro-Optic Systems

Image stabilization (IS) is a family of techniques used to reduce blurring associated with the motion of a camera during exposure. Usual electro-optic systems are embedded inside Gimbal which perform a coarse stabilization. Specifically, it compensates for pan and tilt (angular movement, equivalent to yaw and pitch) of a camera or other imaging device. Nevertheless, the remaining micro vibrations inside the Gimbal generates blurry images from high resolution (small pixel) detectors during exposure time in narrow field of view (FoV).

Depending on the optical configuration and the detector type of the customer camera or electro optic system, CTEC can develop either embedded XY or Tip Tilt stages (Beam or Fast Steering Mirror, Point Ahead Mechanism,…) with their related controllers to move respectively a focal lens, a detector or a mirror in order to actively compensate the optical disturbances. Note that both microscanning & optical stabilisation functions can be performed simultaneously with the same piezo stage. This fine stability control of the line of sight is also very useful for Laser pointing on targets for identification, surveillance and recognition (ISR) systems as well as on optical detectors for free space optical communication systems.

Anti-blurring for imaging systems using a tilting mirror

Beam Wander Correction and Beam Shapping

Graphic without beam correction

Graphic with beam correction using an FSM

Direct energy weapons (DEW) use high energy lasers (HEL) to destroy a target such as a missile or a drone, or to make it inoperative. The laser power of such weapons varies from several kW up to 300 kW. To make sure a laser weapon is efficient, the laser beam must heat the targeted area with a focused beam at a constant place. This ensures the targeted material to heat up and ultimately be destroyed. When the laser beam goes through atmospheric turbulences, its mean position can be randomly deviated. This results in the beam power being diluted in a larger area on the target surface, leading to a lower power density.

To compensate this deviation, a fast-steering mirror (FSM) can be used to stabilize the laser position according to the atmospheric turbulences. CTEC have been delivering several COTS and customised fast-steering platforms for high energy laser applications (Direct Energy Weapon or laser welding and cutting). The steering platform is designed according to the mirror substrate and optical performances required in the laser process and system. Our fast steering mirror solutions, based on different platform designs, welcome either glass or silicon carbide mirror substrates. These FSM are controlled by CTEC driving electronics, according to dynamic specifications.

Download our

micro-scanning brochure

Practical Applications of Optronics Technologies

Super Resolution IR Camera

Optronics

IR Camera

Defence systems

The active IR camera captures thermal images by detecting heat emitted by objects and enhancing them sometimes with laser illumination, but limited resolution and image distortions can make it difficult to see fine details. By integrating the CTEC XY25XS micro scanning piezo stage, the camera achieves higher spatial resolution, improved stability, reduced image distortions, and shows small temperature variations more clearly. This enhanced performance is ideal for applications such as defence systems (armed vehicle sights, border monitoring, and air defense), military and civilian monitoring, and industrial inspection.

High Performance IRST System

Optronics

IRST

Anti-Blurring

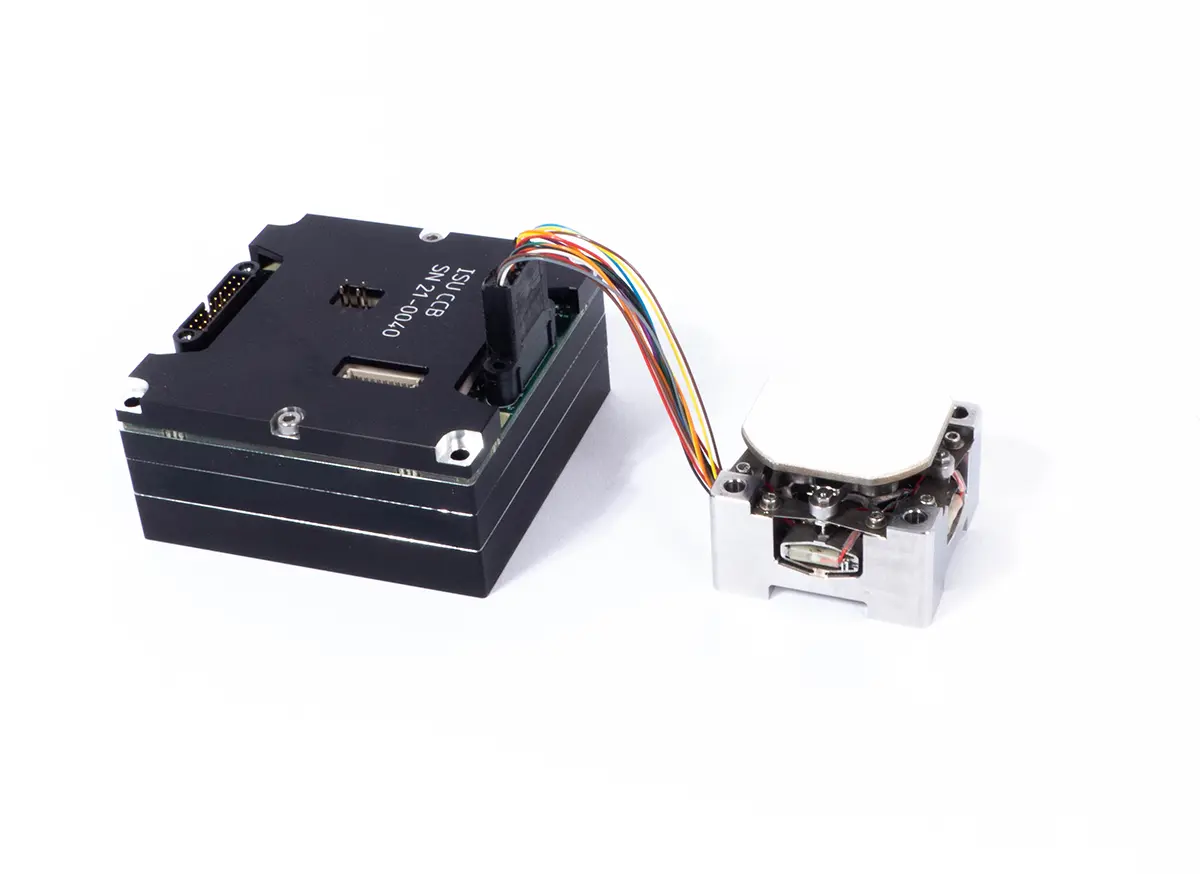

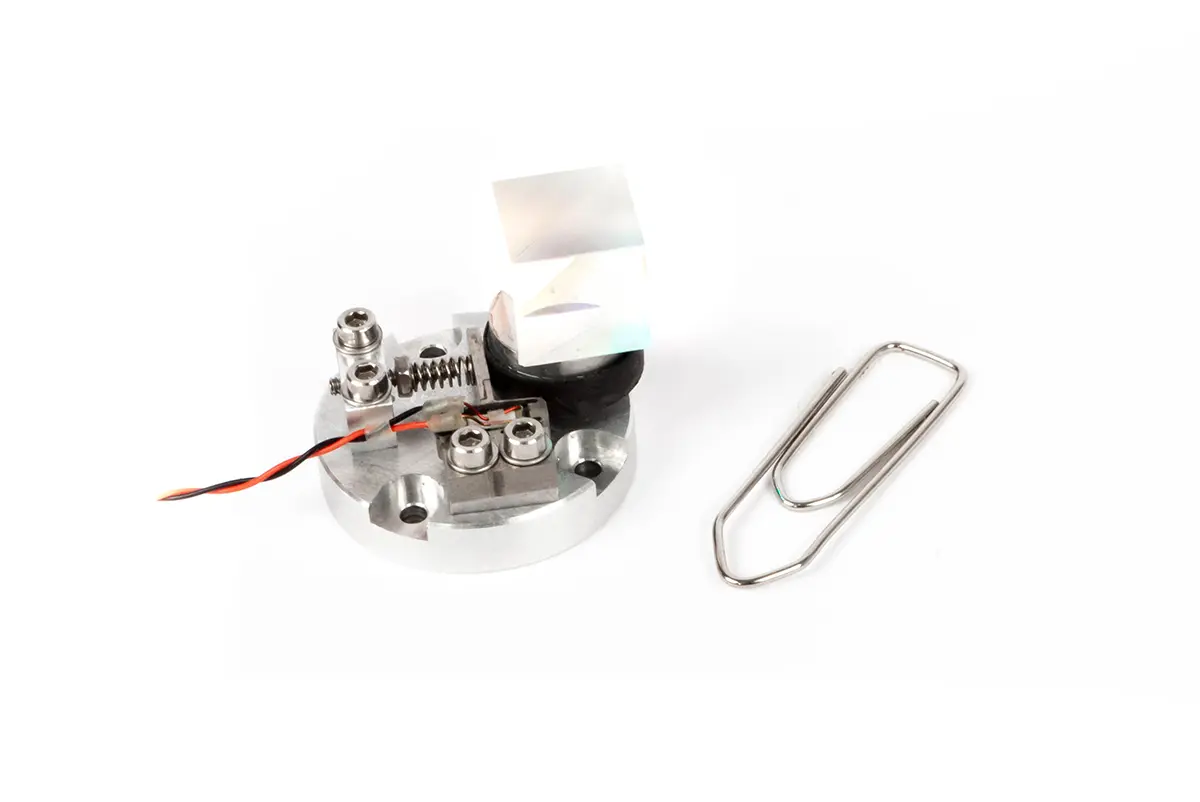

The Infrared Search and Track (IRST) system passively scans wide areas to detect and track objects that emit infrared radiation. To achieve a large field of view, some imaging systems use tilting mirrors to sweep the scene. However, mirror motion during image acquisition can generate a blurred image and cause loss of information while the sensor transfers data to the control system. By implementing a CTEC back scanning solution based on a secondary piezo (TT60SM or DTT35XS) or magnetic fine and fast steering mirror (M-FSM), the system compensates for the primary mirror motion, ensuring a stable image on the detector and continuous scene coverage for high-quality imaging.

High Precision Gimbal Stabilization

Optronics

Gimbal

Image Stabilisation

The Airborne Gimbal Stabilization System rotates to capture high-resolution images and is integrated into airborne platforms such as aircraft or UAVs. The platform generates micro-vibrations that remain even inside the gimbal, which can blur images from high-resolution (small pixel) detectors during exposure time in narrow fields of view (FoV). By integrating a CTEC XY or Tip Tilt stage or Fast Steering Mirrors, the system actively compensates for these micro-vibrations, maintaining a stable line of sight and significantly improving image quality. This robust system can also be used on naval vessels or vehicle-mounted optical platforms.

Would you like to integrate these features into your optronic systems?

Our teams support you at every stage, from defining your needs to full integration.