Publications

Categories

- (34)

- (9)

- (3)

- (143)

- (18)

- (7)

- (4)

- (8)

- (9)

- (17)

- (2)

- (104)

- (7)

- (14)

- (7)

- (1)

- (1)

- (6)

- (155)

- (20)

- (2)

- (5)

- (111)

- (35)

- (11)

- (4)

- (59)

- (18)

- (3)

- (7)

- (62)

- (18)

- (5)

- (24)

- (7)

- (12)

- (1)

- (2)

- (2)

- (1)

- (1)

- (14)

- (13)

- (4)

- (6)

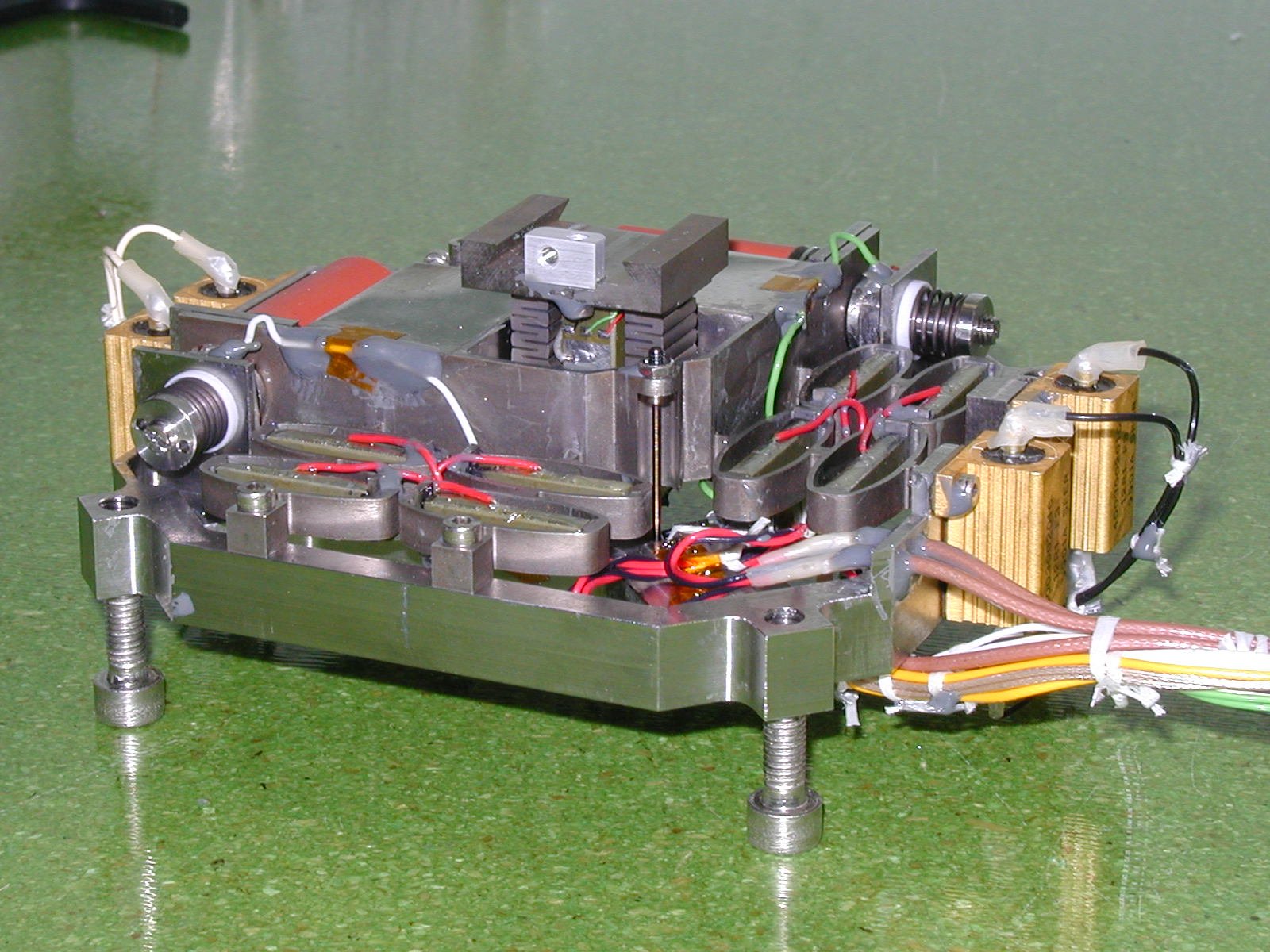

Scanning piezo mechanisms Rosetta Fligth model

19 June 2023

The MIDAS (Micro Imaging Dust Analysis System) instrument jointly developed by IWF Graz (AT) and the Solar Space Division of ESA/ESTEC (NL) will flow on ROSETTA and will analyse the dust of the 46P/Wirtanen cometa using an Atomic Force Microscope (AFM).

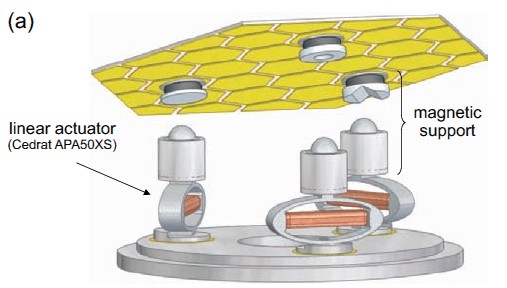

Segmented bimorph mirrors for adaptive optics:segment design and experiment

19 June 2023

This paper discusses a concept of light weight segmented bimorph mirror for adaptive optics. The segment consists of a monocrystal Silicon substrate actuated by an array of in-plane piezoceramic (PZT) actuators with honeycomb electrodes. The paper focuses on technological aspects of the segment design which are critical for space applications and describes a single segment demonstrator. The morphing capability of the segment is evaluated experimentally. The paper also discusses the local deformations (dimples) associated with the shape of the electrodes acting on the PZT array.

Self-tuning semi-active tuned-mass damper for machine tool chatter suppression

19 June 2023

Tuned mass dampers are simple and efficient devices for suppression of machine tool chatter, which is one of the principal effects limiting productivity in many machining processes. However, their effectiveness depends on a proper tuning of the damper dynamics to the dynamics of the machine. This involves the dynamic characterisation of the machining process, in order to identify the critical resonance frequency, and the possibility of matching the resonance frequency of the damper to frequency. The difficulty of meeting these two requirements has been limiting the use of tuned mass dampers in industrial applications.

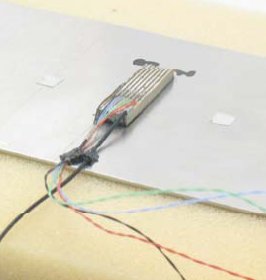

Piezo-composite transducer for mode and direction selectivity of Lamb waves

19 June 2023

Ultrasonic-based SHM (Structural Health Monitoring) applications commonly rely on the use of piezo-electric patches to emit and receive ultrasonic waves. The objective is to study the propagation of the waves through a structure to assess its structural integrity. Because of the elevated number of echoes and possible modes of propagation of the waves within the structure, those applications suffer from a burden of signal processing. This paper presents a composite piezo-electric patch that was designed and successfully tested for reducing the complexity of the SHM detection schemes by selecting the mode and direction of the Lamb waves received. The piezo-composite is composed of a row of eight independent ceramic pillars separated with polymer, so it is a 1-D matrix of independent piezo-patches. Used with adequate electronics and signal processing, it was shown that it allowed selecting the direction and the mode of the Lamb waves.

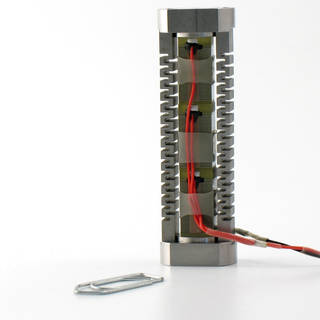

Piezoelectric Actuator for precise and fast Oval Pistons manufacturing

19 June 2023

Piezoelectric Actuator and related driving & control electronic for precise and fast «Oval Pistons» manufacturing Oval pistons are used in all automotive industry. Every vehicle, motorbike, car and truck uses oval pistons. The reason is that pistons in these vehicles are working in very hot environment and as a consequence, the external shape deformation induced thermal growth of the piston is compensated by these «ovalities» (oval shapes).

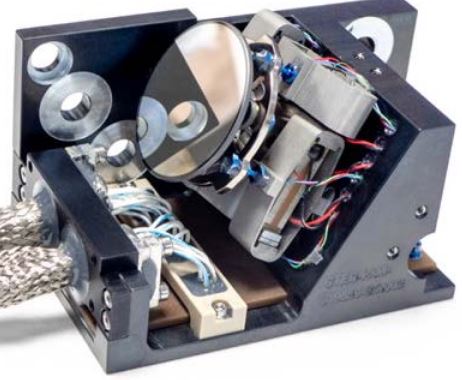

Point Ahead Mechanism for Deep Space Optical Communication Development of a New Piezo-Based Fine Steering Mirror

19 June 2023

The purpose of this paper is to present the development of a novel tip-tilt mechanism, with integrated optics, designed for the JPL Deep Space Optical Communication (DSOC) module of the upcoming Psyche mission (2022 launch). This paper presents the design, assembly and tests of the produced models. Regarding the design phase, an emphasis was put on the mirror calculations to ensure that the required flatness would be maintained after integration, and that the part would withstand the thermal/mechanical environment. The actual optical measurements performed after assembly are also presented. The qualification results for a new alpha-case removal process for titanium parts are presented. Tests results are especially interesting

regarding the temperature behavior of the mechanism, impact on the stroke, and strain gage sensor feedback.