Publications

Categories

- (34)

- (9)

- (3)

- (143)

- (18)

- (7)

- (4)

- (8)

- (9)

- (17)

- (2)

- (104)

- (7)

- (14)

- (7)

- (1)

- (1)

- (6)

- (155)

- (20)

- (2)

- (5)

- (111)

- (35)

- (11)

- (4)

- (59)

- (18)

- (3)

- (7)

- (62)

- (18)

- (5)

- (24)

- (7)

- (12)

- (1)

- (2)

- (2)

- (1)

- (1)

- (14)

- (13)

- (4)

- (6)

Investigations on a directly coupled piezoactuated tool feed system for micro electro discharge machine

19 June 2023

A directly coupled piezoactuated tool feed mechanism is proposed and a prototype micro-electrodischarge machine (micro-EDM) is developed. The piezoactuator is used to feed the tool and also to sense the tool displacement from a reference position. The hysteresis behavior of the piezoactuator is also incorporated through an electromechanical model for estimating the actual tool displacement. Simulation results for piezoactuator displacement are compared with the experiment and a maximum error of 15% was observed. Further, in order to control the tool feed rate during machining, a tool feed controller based on the gap voltage feedback is developed.

Electro-fluidic components based on smart materials for aircraft electro-hydraulic

19 June 2023

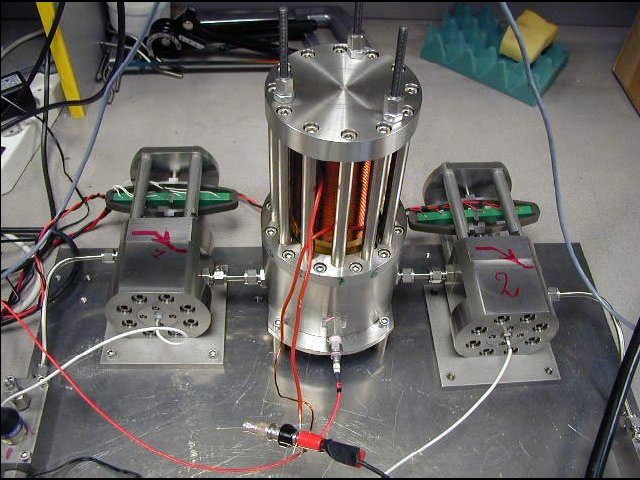

In the context of a more electrical aircraft, in order to explore the feasibility of non usual solutions, electro-fluidic components based on smart materials and new Electro-Hydraulic-Actuators (EHA) concepts, based on active valves and magnetostrictive vibrating pump, have been studied. Active valves based on different magnetostrictive and piezoelectric actuators have been designed, realised, tested and compared. The magnetostrictive version uses a new Amplified Magnetostrictive Actuator (AMA) based on a stack of Giant Magnetostrictive Materials (GMM) and placed inside an elliptical amplification ring.

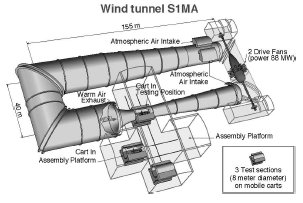

Wind-tunnel tests of a helicopter rotor with active flaps

19 June 2023

Within the frame of a project called DTP RPA (Développement Technique Probatoire Rotor à Pale Active), also known as Active Blade Concept, carried out in cooperation between ONERA, Eurocopter, DLR and Eurocopter Deutschland, a four-bladed Mach-scaled rotor was tested in December 2005 in ONERA S1 Modane wind-tunnel. The main objective of this test was to validate the concept of using active flaps located on the trailing edge of the blades of the main rotor of a helicopter to decrease the vibration level generated by this rotor.

Extreme performance of piezo system: High stroke, high frequency, high temperature

19 June 2023

This paper presents research and development results of the high performances piezoelectric actuators. Performed studies were concentrated on the improvement of three major parameters: stroke, maximum driving frequency and operational temperature. Two, new actuators were presented and described in this paper. First presented actuator has increased maximum displacement. This actuator has doubled the stroke of standard, long stroke actuators. Improvement of the second actuator was concentrated on increase of constant driving frequency. Finally, special encapsulations designed for both actuators allow using them at high temperatures. Development of these two, new actuators was done simultaneously to the improvement of the electronics. High power amplifier presented in this paper provides sufficient current to drive both actuators at high frequencies.

Force Stepping Piezo Actuator : a motorised solution for high resolution positioning and external forces resistance

19 June 2023

Typical holding force of piezo motors is defined by friction force, required to make motor move. However, increase of friction force is not inconsequent for motor performances in terms of speed, max motion force and lifetime (tribology). In this paper, a new motor, offering high resolution positioning and holding position when unpowered, is presented. Based on a Stepping Piezo Actuator [1] at its core, this new design decouples the outer forces from the most sensitive parts of the motor. This allows the motor to propose a high force/mass ratio and sustain even higher forces without supply. Results obtained on prototype are presented, giving the reader the benefits of proposed technology.

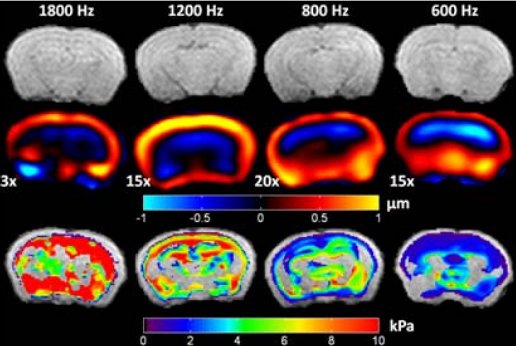

Frequency Dependence of Mouse Brain Tissue Stiffness Measured in vivo with MR Elastography

19 June 2023

Magnetic resonance elastography (MRE) is a non-invasive imaging technique for quantitative measurement of the mechanical properties of biologic tissue in vivo [1]. The clinical interest in MRE has largely been driven by the direct relationship between tissue health and stiffness. As a result, MRE may provide significant clinical value for the non-invasive diagnosis of pathology and response to therapy by tracking tumor development and monitoring therapeutic response. MRE may also have considerable value in the development of treatment protocols in pre-clinical, rodent models of cancer. Because of cost and versatility, the mouse, in particular, is widely employed in oncologic studies. To resolve its small anatomic features, MRE experiments in mice must be performed with high driving frequencies (>600 Hz). However, high-frequency waves exhibit increased attenuation, reducing wave penetration depth and making it more difficult to impart motion deep into tissue with sufficient amplitude to overcome background noise. Also, biologic tissue is viscoelastic; hence, its response to load depends on the driving frequency. Recent MRE studies in mouse brain have been performed in high-field scanners (7 – 11.7T) at single driving frequencies of 1000 and 1200 Hz [2,3]. Here, we perform elastography in mouse brain tissue at 4.7T and report viscoelastic material properties over a range of driving frequencies (600 – 1800 Hz).