System Engineering

What do we address?

Cedrat Technologies (CTEC) is specialized in the development and manufacturing of piezoelectric, magnetic and other smart materials-based systems. Our primary skill is to create advanced mechatronic solutions for our clients, providing significant added value to their systems’ integration. The functions and solutions we supply represent technological breakthrough, enabling them to make major performance improvements in their processes and applications. From conceptual design to industrialization, going through simulation, modelling, prototyping and testing CTEC can assist you through long term project.

We address diversified markets described here, with various functions such as:

- Micro & fast positioning,

- Micro-scanning, pointing,

- Shaking, force testing,

- Vibration assistance,

- Ultrasonic processing,

- Active damping,

- Position sensing,

- NDT & health monitoring,

- Fluid control,

- Energy harvesting.

Why engineering?

The specific developments at CTEC emerge from needs that our clients have been unable to satisfy due to lack of either COTS solutions or expertise available on the market. Our clients entrust us with engineering tasks to solve problems through technological challenges, which can lead to the generation and the share of intellectual property.

Custom development and engineering differ from COTS products in their ability to adapt to your specifications. At CTEC, we have the expertise to address custom developments for our clients. We can guide and advise you towards a trade-off solution analysis and a specific workpackage breakdown best suited to your needs. In Space for instance, we manage the increase of TRL via a sequence of Engineering Models (EM), Qualification models (QM) and Flight Models (FM).

What do we develop?

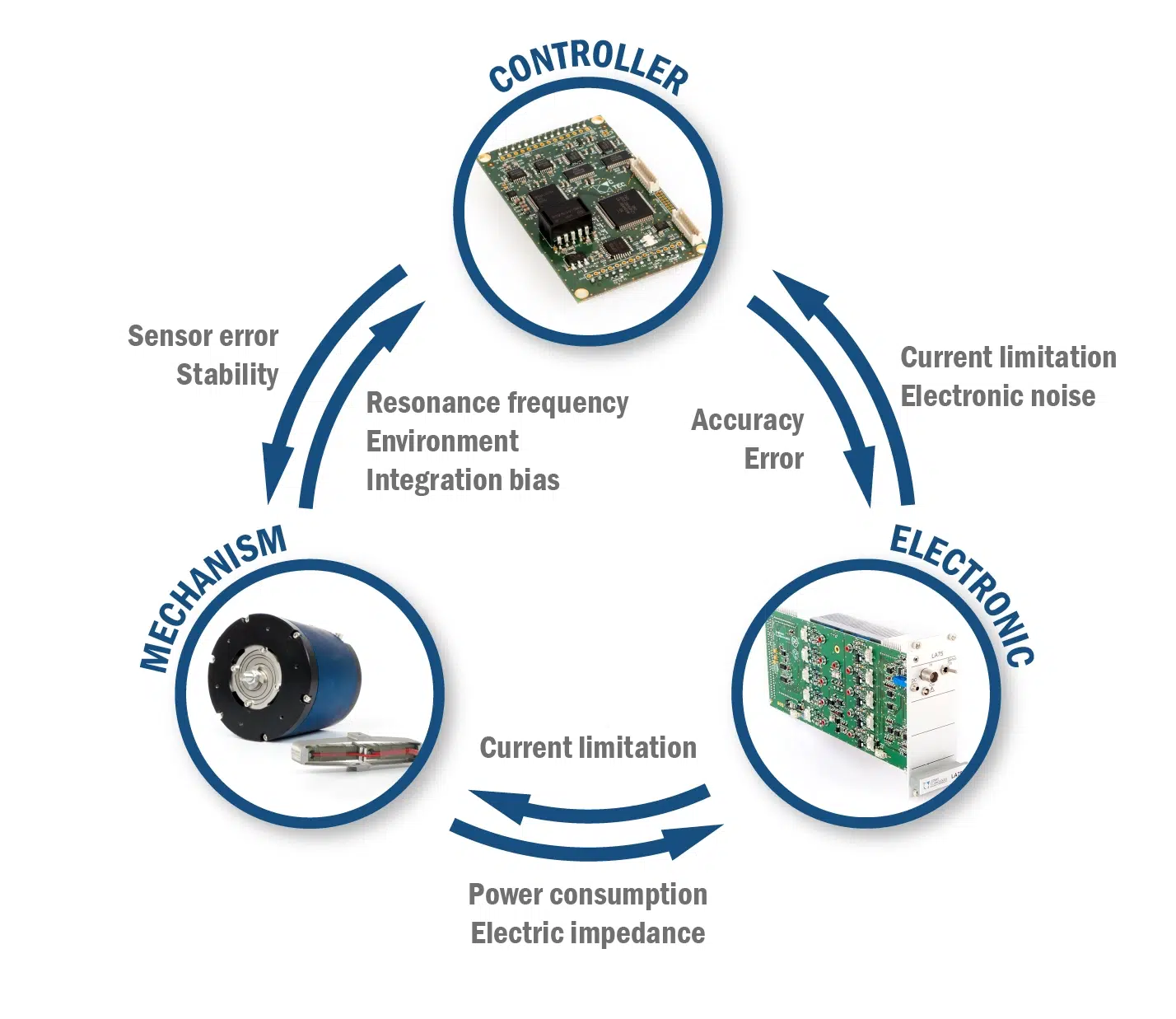

We strive to innovate and develop systems that meet the evolving needs of our clients. For CTEC, a “mechatronic system” consists typically of the combination of 3 functions:

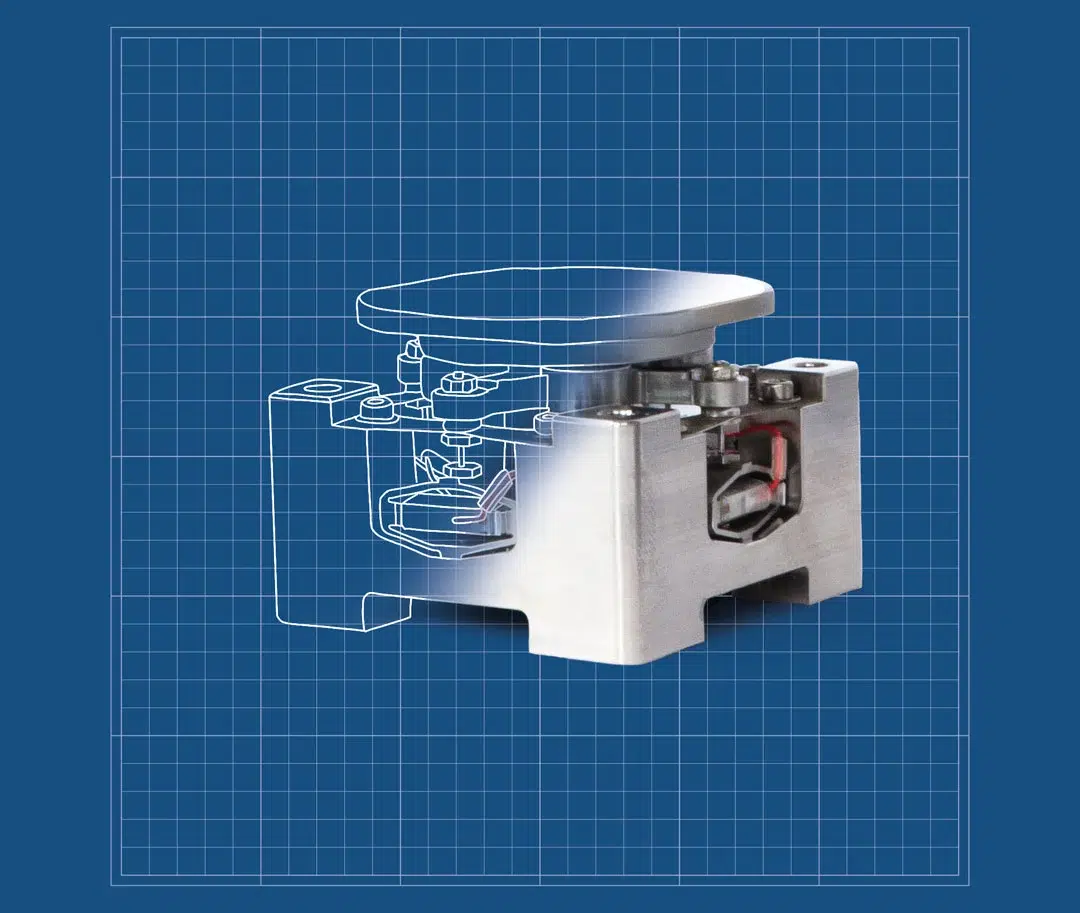

- A mechanism with piezoelectric or magnetic actuators and sensors,

- A dedicated electronic to operate the mechanism,

- A custom software managing the control loop to reach the desired performances.

>> Each of these functions can be customized on demand according to the application.

The combination of these 3 coupled functions requires diverse and complementary skills. A mechatronic project management at CTEC consists in coordinating the actions of our technical teams (electro-mechanical, electronic, control, lab, method & production) all together driven through a quality environment, milestones & compliances agreed with the client.

What is the origin of engineering capacity?

Our DNA comes from space applications. For more than 25 years, CTEC has been working with clients such as AIRBUS DS, CNES, ESA, NASA, and others. This aerospace heritage has built a rigorous approach to project management, justification documents, and strict adherence to standards. Our technology has proven its legitimacy in the space field, and in parallel, CTEC has applied and adapted its knowledge through COTS, and services for other markets. This experience enables us to bring the level of expertise required for space applications to new fields by adapting the roadmap to meet our clients’ specific requirements.

How do we proceed?

Our sales engineers support you in defining the specifications and road map for developing your dedicated solution. Our comprehensive support throughout your project’s lifecycle includes:

- Feasibility and pre-design,

- Detailed design,

- Manufacturing, Assembly, Integration & Testing (MAIT),

- Qualification and industrialisation.

CTEC can also adjust this generic development roadmap or tasks breakdown according to your requirement or constraint

Our skills

To bring your project to success, CTEC can rely on its internal engineering skills in the following fields:

Additionally, CTEC is adept at creating and handling IP. Specific contracts and patents can be established for shared inventions or business licenses. CTEC offers:

- Industrial projects leading to turn-key solutions,

- R&D collaborative projects funded by the European Commission (Horizon Europe projects) or other frameworks (Eureka, national projects),

- Manufacturing for customers under QA standards (ECSS, MILSTD, ANSI/IPC3),

- Technology transfers (Licensing),

- IP management and patent support.