Publications

Categories

MRF actuator for high force locking and damping applications

12 January 2010

The MRF actuators are new electromechanical components using Magneto Rheological Fluids (MRF). These smart fluids are characterized by their ability to change their rheological properties versus applied magnetic field. They can switch from a liquid to an almost solid body. This effect is reversible and operates within a few milliseconds. MRF are used to create controllable dampers, smart shock absorbers or brakes. After having developed several MRF actuators with an original characteristic (presenting a blocking force at rest), Cedrat Technologies was asked to develop a very challenging new MRF damper which goal can be summed up with a few words: “small size and high force”.

MRF actuators

7 January 2008

The MRF Actuators is a new electromechanical component using Magneto Rheological Fluids (MRF). The benefit of these smart fluids is their capability to alter their rheological properties – their viscosity in particular – compared to applied magnetic field.

MRI compliant micro-motors for medical and biomedical applications

19 June 2023

The performances offered by Magnetics Resonance Imaging (MRI) are widely recognized and used by practitioners. Mainly used for diagnostic issues, MRI becomes more and more an interventional tool in image-assisted classic or robotic surgery. However, constraints imposed by the MRI strong magnetic field and strong magnetic gradients in terms of material and architecture are often obstacles to MRI guided robotics. Designers have to deal with the few choices offered to them to build a robot which will be able to respond to severe specifications, in terms of space limitations, magnetic field sensitivity and image impact. Piezoelectric micro-motors are good candidates to fulfil these requirements in several fields of applications.

MSPA motors for rotary motions

19 June 2023

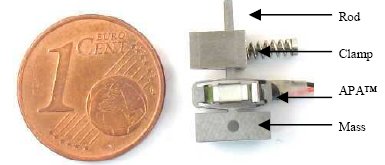

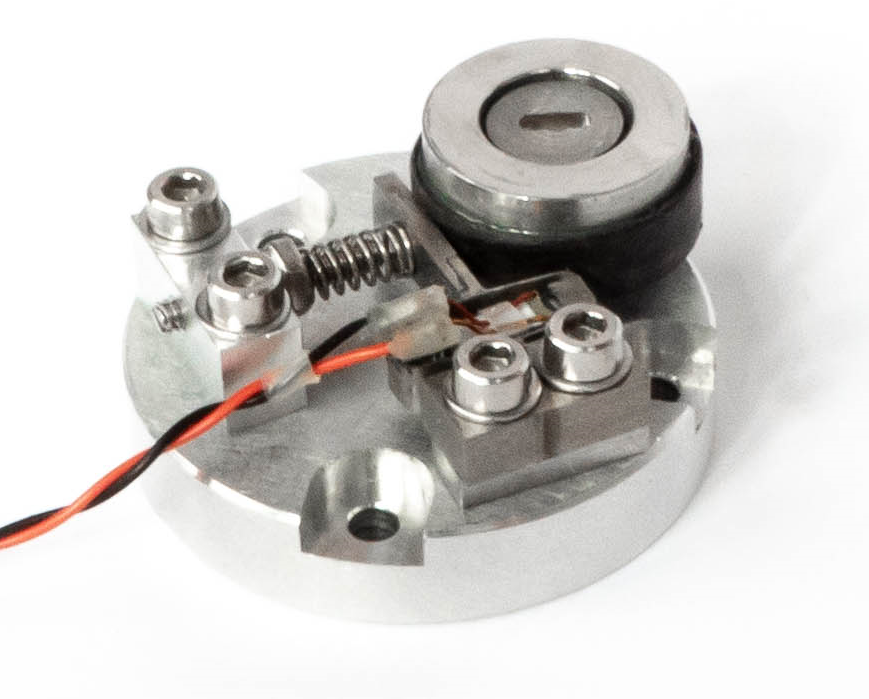

Modular Stepping Piezoelectric Actuators (MSPA) are inertial motors working under the stick-slip principle [1].

The advantages of rotary MSPA are unlimited stroke, torque at rest, high resolution, nonmagnetic and vacuum compatibility.

This paper presents the new MSPA developments regarding rotary motion at Cedrat Technologies for macro and

micro sizes MSPA. These progresses follow the previous technical investigations around noise reduction, miniaturization

at low voltage and the integration of MSPA modules [2]. In this paper two rotary piezo motors are presented: The first

one is a macro size MSPA based on APA40SM. It is developed to work under nuclear environment: operational temperature

up to 70 degrees, vacuum, 5 Tesla magnetic field and high radiation fields (3,5 kGy/hour gamma radiation power

and 500 Mn/(cm².second) neutron radiation power). The second is a micro size MSPA based on APA30uXS. This motor

is used for embedded application such as nonmagnetic shutter.

Nanometric linear piezo-actuator with integrated Strain Gages for high stability positioning

19 June 2023

Many applications require a mechanism capable of nanometric resolution position tuning, and with the ability to maintain perfectly this position for a long time (more than several days). For those applications, piezo-actuators are a perfect fit since they easily provide nanometric resolution. However, they require the use of a position sensor to be able to maintain stable position over time. Until now, the long-term stability of strain gages (SG) for position measurement was questionable. Using its extensive know-how of strain gages integration and new instrumentation equipment, Cedrat Technologies has managed to demonstrate the ability of a piezo-mechanism with integrated strain gages sensors to achieve nanometric position stability. This technology opens new possibilities for industrial, aeronautical, and space applications.

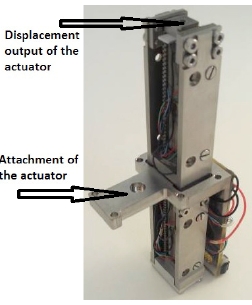

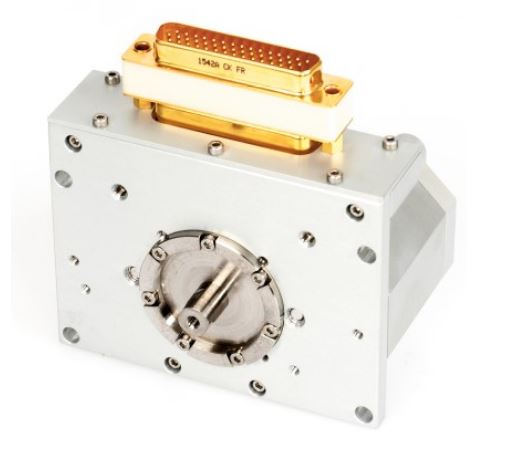

Nanometric positioning with IASI-NG Beam Splitter Mechanism Actuator

19 June 2023

This paper presents a piezoelectric motor which provides linear motion and very high resolution (40 nm steps). First, the space application (IASI-NG instrument onboard METOP-SG satellite) and associated performance requirements are presented. The internal architecture of the motor and its main components are then explained. A first focus is done on the experimental verification of the threaded interface lifetime which is a key element of the mechanism. A second focus is on the nanometric position test bench. Achieved results are provided for resolution, motion quality and position stability. Finally, results from the

vibration test campaign are presented