Publications

Categories

Thermal vacuum behaviour of a stepping piezo actuator

19 June 2023

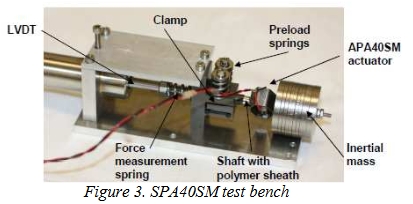

The presented work illustrates the design of a new high force Stepping Piezoelectric Actuator (SPA) and describes its Thermal Vacuum testing as performed by ESTL, in order to investigate SPA compatibility with vacuum environment within a wide temperatures range; from +60°C down to -180°C. A dedicated test bench was designed, in order to check motor force and speed for all performed tests. Instrumentation, testing and observations about tribological behaviour of friction interface have been realized by ESTL, showing interesting perspectives.

Characterisation of magneto-rheological fluids for actuators applications

19 June 2023

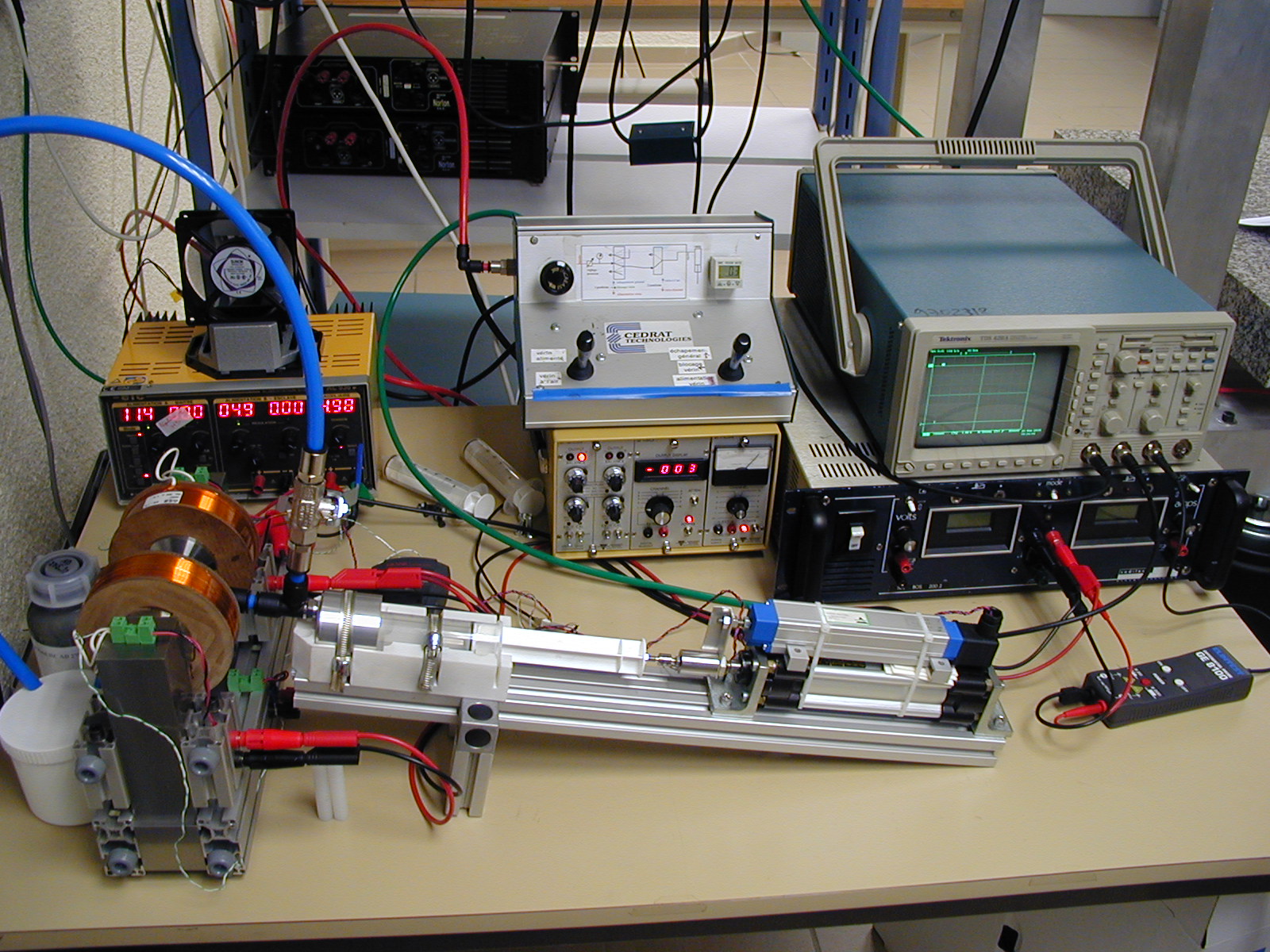

Magnetorheological fluids (MRF) are magnetically controlled fluids and they find more and more industrial applications in actuation functions. These include shock absorbers, semi-active dampers, clutches, brakes, haptic actuators & devices. Several of these applications have been studied by Cedrat Technologies for its industrial customers, and a device-oriented test bench has been developed in order to characterise the magneto-mechanical properties of MRF such as the magnetisation curve, the yield stress ….

Giant dynamic strains in magnetostrictive actuators and transducers

19 June 2023

Magnetostriction occurs in the most ferromagnetic materials and leads to many effects [1,2]. The most useful one to refer to is the Joule effect. It is responsible for the expansion (positive magnetostriction) or the contraction (negative) of a rod subjected to a longitudinal static magnetic field. In a given material, this magnetostrain is quadratic and occurs always in the same direction whatever is the field direction. Giant Magnetostrictive Materials (GMM), especially Rare earth-iron discovered by A.E.Clark [3], feature magnetostrains which are two orders of magnitude larger than Nickel. Among them, bulk Tb0.3Dy0.7Fe1.9, called Terfenol-D, presents the best compromise between a large magnetostrain and a low magnetic field, at room temperature.

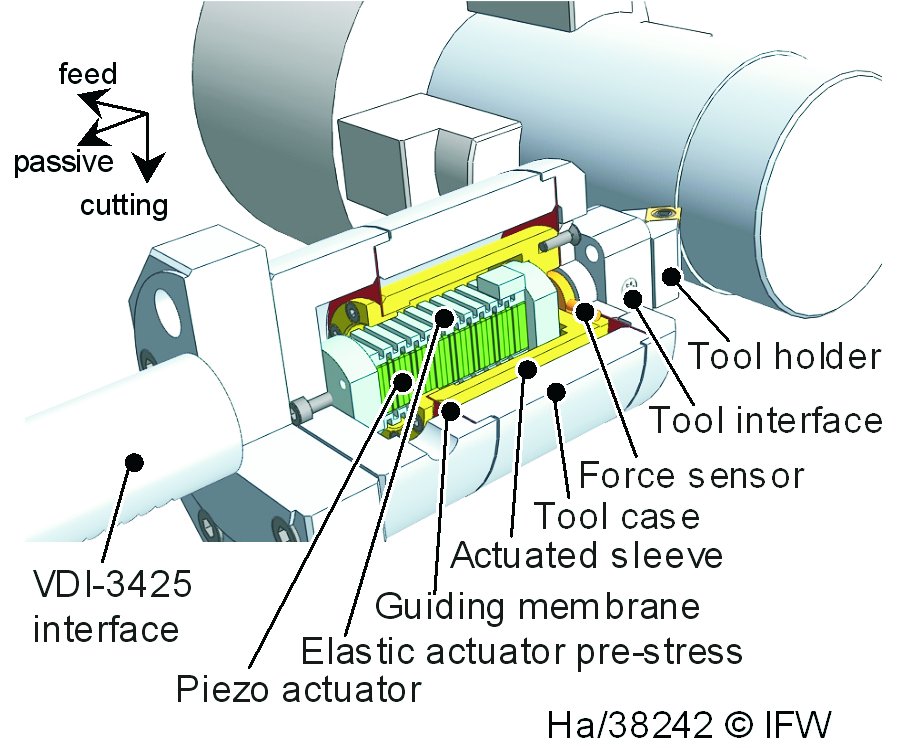

Tool adaptor for active vibration control in turning operations

19 June 2023

A tool adaptor with built-in active vibration damping device to dynamically stabilize the turning process is presented in this paper. It can be used in standard CNC-lathes and allows the usage of off-the-shelf tool heads. The vibration compensation system is based on a multilayer piezoactuator that is in collocation with a piezoelectric force sensor. An analogue controller based on the integral force feedback method is used for active damping.

High performance synthetic jet actuator for aerodynamic flow improvement over airplane wings

7 June 2018

In the framework of a French National Program, the project ASPIC aims at using synthetic jet actuators to improve aerodynamic performance of aircrafts. The partnership between Cedrat Technologies (CTEC) and the French Aerospace Lab (ONERA) in this project has led to design, manufacture and test a high efficiency innovative synthetic jet actuator. This device relying in part on an ONERA patent is actuated by a CTEC amplified piezoactuator (APA). Its aim is to provide a high speed synthetic jet compatible with flow control application on aircrafts or any other vehicle. Latest available test results and experimental performances of the ASPIC synthetic actuator are presented in this document: in particular, a peak exit velocity of 135m.s-1 during suction, and of 150m.s-1 during blowing, with an optimal actuation frequency bandwidth between 200 and 300Hz.

Driving control electronics piezoelectric actuators space applications

19 June 2023

Piezoelectric mechanisms are more and more used in space applications requiring precise positioning functions for scientific payloads or optical functions. Indeed, piezoelectric actuators are generally deemed of being good candidates for driving and control compact mechanisms.