Publications

Categories

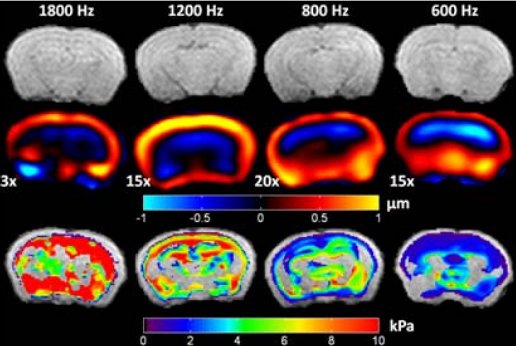

Frequency Dependence of Mouse Brain Tissue Stiffness Measured in vivo with MR Elastography

19 June 2023

Magnetic resonance elastography (MRE) is a non-invasive imaging technique for quantitative measurement of the mechanical properties of biologic tissue in vivo [1]. The clinical interest in MRE has largely been driven by the direct relationship between tissue health and stiffness. As a result, MRE may provide significant clinical value for the non-invasive diagnosis of pathology and response to therapy by tracking tumor development and monitoring therapeutic response. MRE may also have considerable value in the development of treatment protocols in pre-clinical, rodent models of cancer. Because of cost and versatility, the mouse, in particular, is widely employed in oncologic studies. To resolve its small anatomic features, MRE experiments in mice must be performed with high driving frequencies (>600 Hz). However, high-frequency waves exhibit increased attenuation, reducing wave penetration depth and making it more difficult to impart motion deep into tissue with sufficient amplitude to overcome background noise. Also, biologic tissue is viscoelastic; hence, its response to load depends on the driving frequency. Recent MRE studies in mouse brain have been performed in high-field scanners (7 – 11.7T) at single driving frequencies of 1000 and 1200 Hz [2,3]. Here, we perform elastography in mouse brain tissue at 4.7T and report viscoelastic material properties over a range of driving frequencies (600 – 1800 Hz).

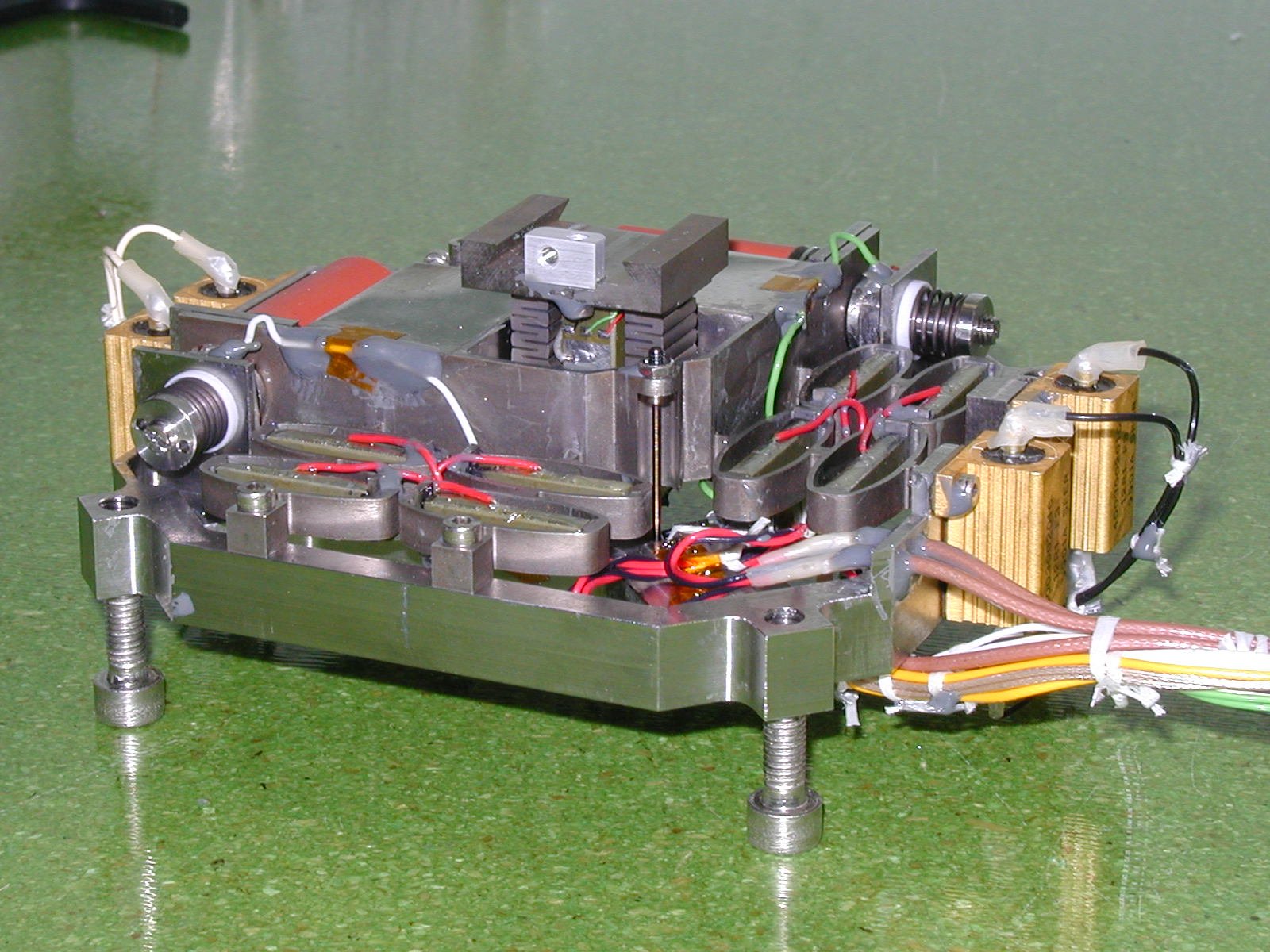

Design and evaluation of a piezo xy stage

19 June 2023

The ROSETTA/MIDAS mission of the Europeans Space Agency (ESA) intends to study the dust collected from the Wirtanen comet using an Atomic Force Microscope (AFM). This instrument utilzes an XY piezoelectric stage to achieve precise positioning in two in-plane orthogonal directions, and a Z actuator to support the needles for the analyses of dust particles in the out-of-plane direction.

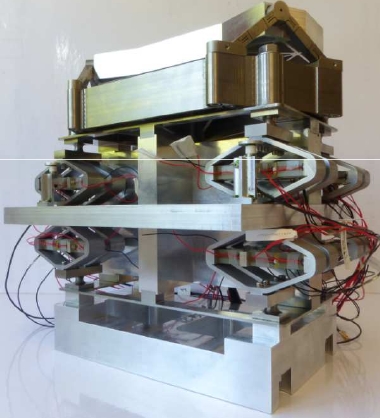

From the Test Benches to the First Prototype of the muFly Micro Helicopter

19 June 2023

The goal of the European project muFly is to build a fully autonomous micro helicopter, which is comparable to a small bird in size and mass. The rigorous size and mass constraints infer various problems related to energy efficiency, flight stability and overall system design. In this research, aerodynamics and flight dynamics are investigated experimentally to gather information for the design of the helicopter’s propulsion group and steering system. Several test benches are designed and built for these investigations

Design and tests of a demonstrator for filet compensation mechanism

5 January 2016

Future matrix sensors will acquire an area on ground and are then susceptible to image shift due to satellite movement during acquisition. Design, Build and Test a breadboard mechanism that could shift telescope line of sight and freeze observed area during image acquisition.

Design of a 2 stages compressor for mobility applications, using compact and efficient Moving Iron Controllable Actuators

19 June 2023

An actuator is rescaled for integration into a compressor used for the liquefaction of hydrogen vapor boil off, into a propellant storage system. The goal is to evaluate the feasibility of liquid hydrogen zero boil off, for long duration storage at 20 Kelvin cryogenic liquid condition. This article presents the actuator trade off, selection and special features imposed by the application. The actuator design is presented, its characteristics are measured, and resulting performances are presented and discussed.

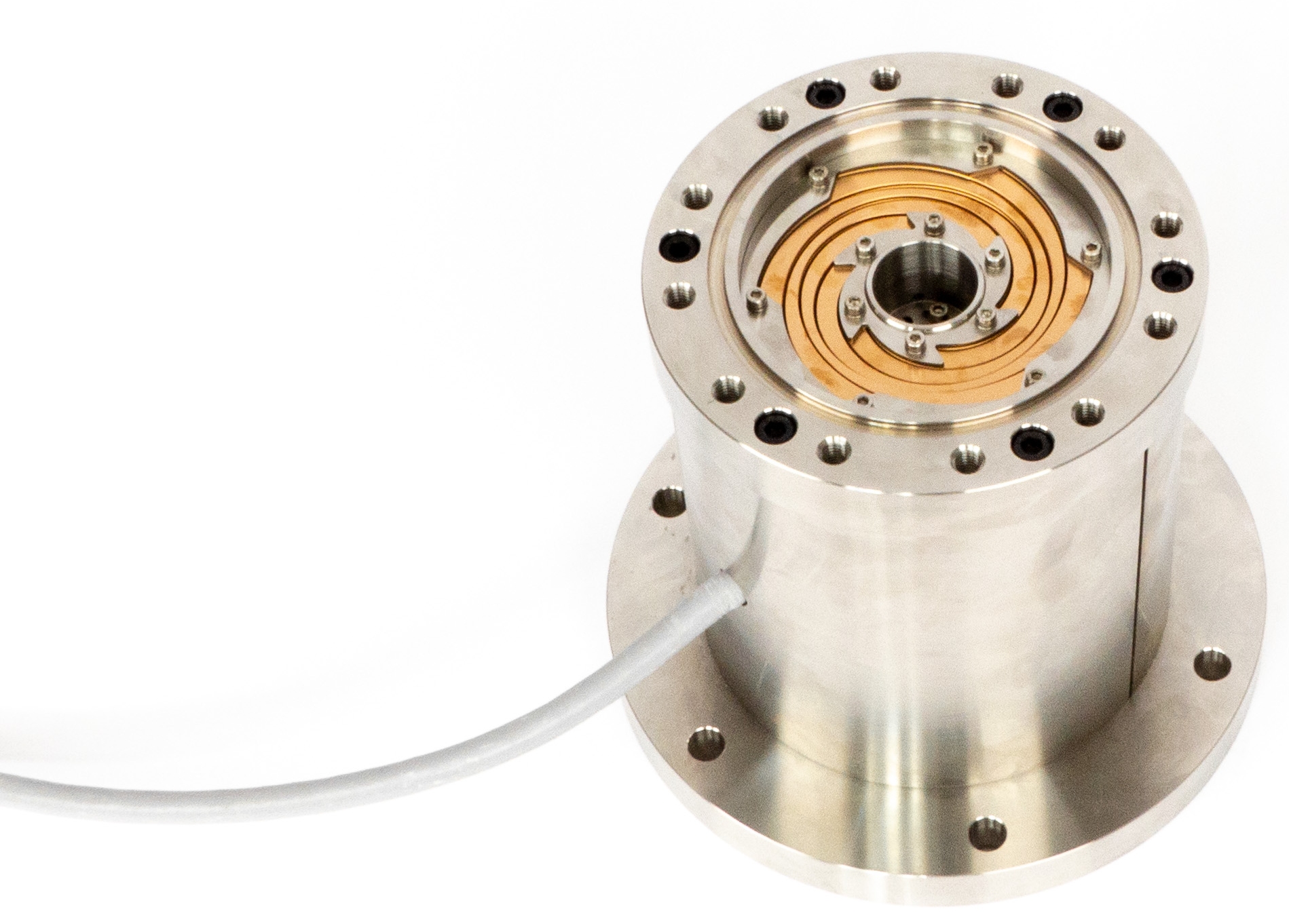

FSPA and BSMA Nanometric positioning actuators for ground and space applications

19 June 2023

Many applications and more specifically space projects show need for a stable sub-micrometre positioning actuator. In order to meet this need, Cedrat Technologies has designed the new FSPA brand. This linear stepping actuator offers sub-micrometric positioning resolution along 5mm stroke combined with high actuation force (>100N) and the ability to hold its position without power.

The IASI-NG instrument is one of the key payload on-board METOP-SG which is a new meteorological satellite for Europe. The instrument is based on a Mertz interferometer and requires a very precise positioning of an optical blade used to separate the interferometer’s branches. A dedicated version of the FSPA, the Beam Splitter Mechanisms Actuator (BSMA) is then developed to achieve this nanometric positioning which is a key parameter for the overall instrument performance.

This paper firsts present the internals of both FSPA and BSMA actuators. Major design differences and their respective impact on the resulting performances are detailed. Results from the acceptance and qualification test campaigns are also presented.