Publications

Categories

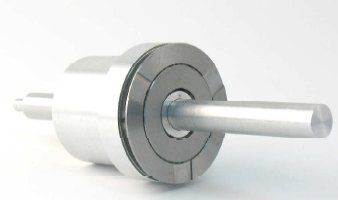

Contactless Torque Sensors based on shaft torsion measurement, compatible with existing shafts

19 June 2023

The torque measurement usually comes from strain gauges bonded on a shatf. the main concern in this measurement is due to the fact that these gauges are also rotating and the integration of electronic on rotating parts is definitely a blocking point.

Linear amplifiers for piezo actuators

1 January 2000

After the development of switching amplifier SA75 for piezoelectric actuator driving, CEDRAT RECHERCHE has developed linear amplifiers. The LA75 electronics are presented in the form of a 19″ rack, and are proposed into various version.

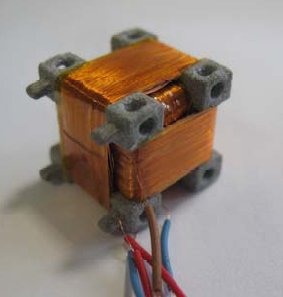

AC magnetic field detection system applied to motion tracking

12 February 2010

In the context of motion tracking and virtual reality, there is a strong need for sensors to monitor the motion of a moving object. These sensors are characterised by their performances (ranges, accuracy, drifts, and susceptibility to the ambient environment) and embedded (small size, light weight). The magnetic technology compared to the mechanical or optical solution allows the working without structural skeleton composed of links interconnected by monitored joints and with possible optical shadows.

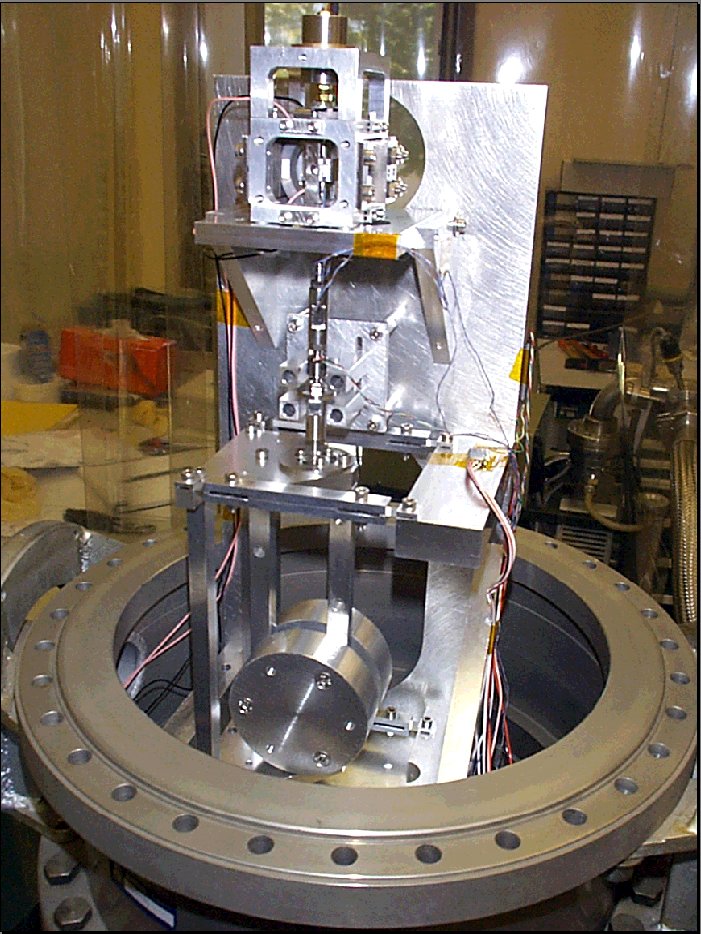

Fine stepping piezo actuator for IASI-NG

7 June 2018

Many applications and more specifically space projects would have use of a stable sub-micrometre positioning actuator. In order to meet this need, Cedrat Technologies has designed the new FSPA brand. This linear stepping actuator offers sub-micrometric positioning resolution along 5mm stroke combined with high actuation force (>100N) and the ability to hold its position without power. Starting from the FSPA, a special version is being developed for the IASI-NG space instrument. This light (500g), fully redundant actuator is designed to achieve 150µm stroke with locking at rest, 60 N force with a 25-50 nm step resolution and resistance to launching. The paper presents the base FSPA actuator and the new high performance space variant.

Lpm motor test

19 June 2023

We are delighted in announcing the successful test of our LPM20 linear piezoelectric motor, carried out in June this year at the CNES (French Agency Space), Toulouse in vacuum conditions.Developed for positioning applications, the piezoelectric motor

has proved to be a very interesting solution thanks to its high massive force, its zero consumption at rest and its high precision. For space applications, it is a question of obtaining an identical behaviour in ambient and in vacuum conditions.

However, the friction drive that is the key to the functioning of the piezoelectric motor, limits the lifespan and poses tribology problems.

Advanced Landing Gears for Improved Impact Absorption

6 January 2008

The presented project ADLAND (AST3-CT-2004-502793) dealt with evaluating the options for adaptive shock absorbers to be applied in aircraft landing gears. Analytical design procedures were developed to simulate different potential design options and a best practice solution determined. The different hardware components regarding adaptive shock absorbers were then developed and tested with regard to adaptive landing gear model. The objectives of the project were: to develop a concept of adaptive shock-absorbers, to develop new numerical tools for design of adaptive absorbers and for simulation of the adaptive structural response to an impact scenario, to develop technology for actively controlled shock-absorbers applicable in landing gears, to design, produce and perform repetitive impact tests of the adaptive landing gear model with high impact energy

dissipation effect, to design, produce and test in flight the chosen full-scale model of the adaptive landing gear.