Publications

Categories

A new amplified piezoelectric actuator for precise positioning and active damping

19 June 2023

Two typical characteristics of direct piezoelectric actuators are displacements of ten micrometers and high stiffnesses. recently, multilayers actuators have been improved, and they now display strains of approximately 1200ppm at low excitation levels (less than two hundred volts). Thus, they are well suited to perform precise positioning of optical devices. But for industrial needs, this performances is still insufficient for positioning devices with larger displacements (in the range of several hundred micrometers).

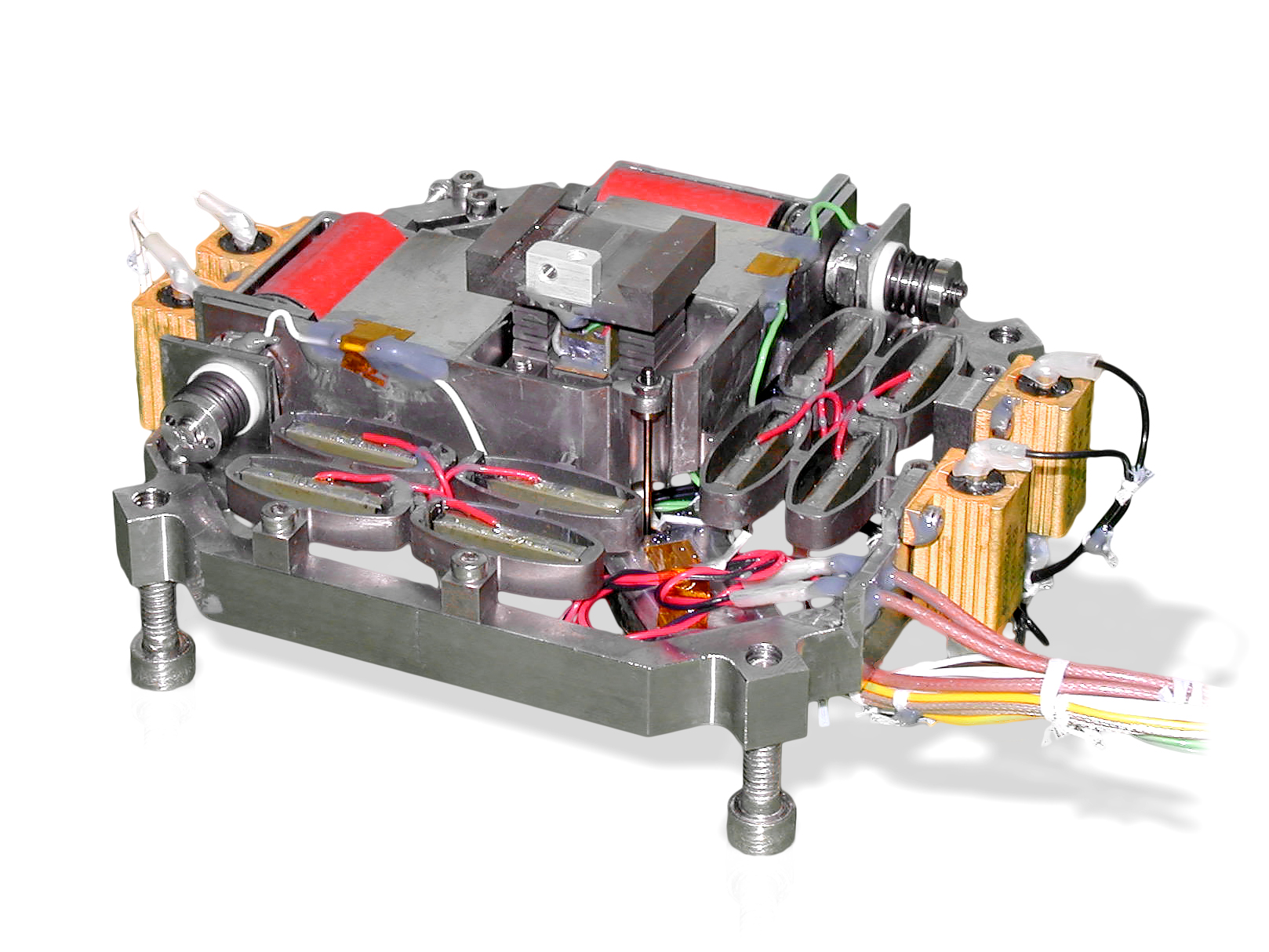

Active washer for smart mechanical linkage

9 December 2017

Bolted connection is the most common way to assemble mechanism. It is widely used in transport domains, such as aerospace, rail, aircrafts… Ensuring that the minimum torque value is always present in the assembly is one of the main maintenance tasks for those components. A possible way to carry out those actions is to implement active component in the bolted assembly. A solution is proposed in this document. Construction, potentialities, performances (based on lap-joint demonstrator) and limitations are identified and confronted to other techniques.

Actuator based on the Thomson effect

1 January 2003

Good limitations of the current in a circuit using an electromechanical breaker suppose a very fast opening of the contacts. Due to the fact that the electrodynamic repulsive forces do not generate enough acceleration, an actuator has to be used to improve the breaker performances. Since a traditional reluctant magnetic device is too slow for the application concerned, a propeller based on the Thomson effect has been chosen. FLUX2D simulations make possible a good understanding of the propeller’s operation and thus the improvement of its design.

Cardiolock: an Active Cardiac Stabilizer

19 June 2023

Off-pump Coronary Artery Bypass Grafting (CABG) is still today a technically difficult procedure. In fact, the mechanical stabilizers used to locally suppress the heart excursion have been demonstrated to exhibit significant residual motion. We therefore propose a novel active stabilizer which is able to compensate for this residual motion. The interaction between the heart and a mechanical stabilizer is first assessed in vivo on an animal model. Then, the principle of active stabilization, based on the high speed vision-based control of a compliant mechanism, is presented. In vivo experimental results are given using a prototype which structure is compatible with a minimally invasive approach.

Smart actuators for aircraft applications

4 January 2003

Smart actuators and intelligent structures receive a considerable interest in the fields of Air & Space, to realise new functions or more efficient functions than passive structures. In these fields, there are needs for actuation means offering high mechanical energy density (product of stroke and force divided by the mass), a low power consumption, a resistance to severe environment (such as vibrations) as well as other case by case needs : High resolution (embedded active optics for cameras and telescopes), fast response (active control of structures shape, active damping of vibration)…

A new Rotating Voice Coil Motor for Meteosat Third Generation satellites

19 June 2023

In the frame of the Meteosat Third Generation project (MTG), the future European Operational Geostationary Meteorological Satellites system, Cedrat Technologies has developed a dedicated actuator for the Scan Assembly mechanism (SCA) made by SENER. Such motors are needed to actuate the SCA on the north/south (N/S) and east/west (E/W) axes. The requirement of precise pointing of the SCA induces very specific characteristics for the motorisation. The motor needed characteristics are: to be free from any cogging, high constant motor [N.m/vW] to have a constant torque over full stroke range, to have a very low hysteresis and to have redundant coils. To meet these stringent requirements, the choice was made to develop a specific Rotating Voice Coil Motor.