Publications

Categories

- (34)

- (9)

- (3)

- (144)

- (18)

- (7)

- (5)

- (8)

- (9)

- (17)

- (2)

- (104)

- (7)

- (15)

- (7)

- (2)

- (1)

- (6)

- (155)

- (20)

- (2)

- (5)

- (111)

- (35)

- (11)

- (4)

- (59)

- (18)

- (3)

- (7)

- (62)

- (18)

- (5)

- (24)

- (7)

- (12)

- (1)

- (2)

- (2)

- (1)

- (1)

- (14)

- (13)

- (4)

- (6)

Space Tribometers: Design for Exposed Experiments on Orbit

12 March 2012

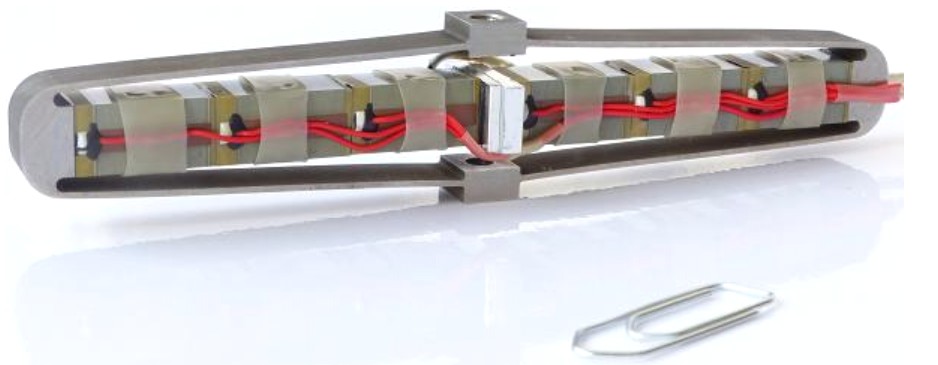

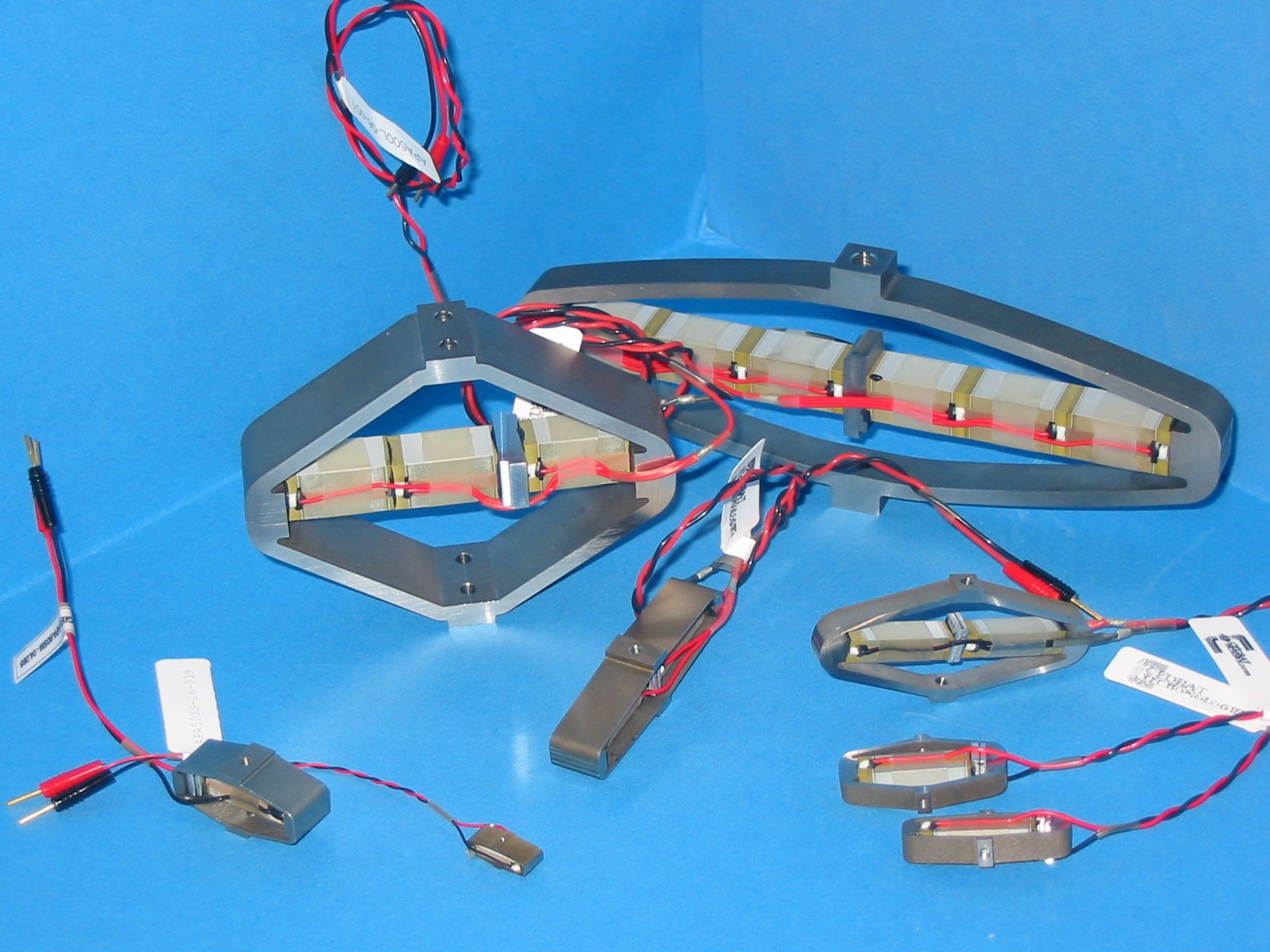

Eight pin-on-disk tribometers have been made for testing materials in space on board the International Space Station. They will be exposed directly to the low earth orbit (LEO) environment on board the ‘‘Materials on the International Space Station Experiments’’ platform where they will experience extreme conditions including atomic oxygen, ultrahigh vacuum, radiation (including UV radiation), and thermal ranges from -40 to 60 C.

Advantages of large piezo actuators and high power drivers for fatigue and fretting test

19 June 2023

Constant expansion of new materials requires fretting or fatigue machines in order to test their failure. In many cases tests must be performed in severe conditions and at high frequency. These requirements come from the use of the materials in highly demanding applications. At the same time it is expected to reduce the time required to characterise such materials. Piezoelectric actuators are more and more common in testing machines, but they still reach limitations in terms of maximum displacement, cycling frequency or power. In order to cope with these issues, Cedrat Technologies has been investigating solutions. In this paper long stroke and high frequency actuators, coupled with powerful driving control are introduced. These actuators are based on piezoelectric materials and can be easily integrated into the fatigue machines. In order to improve precision of these tests, two of the most common displacement sensors used in smart actuators are also presented in this paper.

Long stroke/High resolution tip tilt mechanism

19 June 2023

Multi degree of freedom (dof) mechanisms are widely required into micro or macro manipulation fields as well as in optronics functions. Commonly available mechanisms may be divided into two main categories. The first is industrial robots (serial or parallel). These offer large range of motion, in rotation and translation. Their resolution is usually limited in the sub-millimeter range. The second category achieves very high resolution motion (sub-nanometer) but is limited to a few decades of microns. A way to combine both long stroke and resolution is to use piezo motors into multi dof mechanisms. The aim of this paper is to present a combination of both advantages into a low volume tripod actuator. The Tripod Actuator by Cedrat Technologies (TrAC) is a 3 dof mechanism offering +/-35° rotation around X and Y axis and a 10mm Z translation stroke into a low volume of Ø50x50mm.

Aero India 2003 Piezo actuators air & space

19 June 2023

Several classes of Piezo Actuators based on low voltages piezo ceramics have been developed by CEDRAT TECHNOLOGIES in order to cover needs for long stroke, precise and/or fast positioning in the fields of air & space applications. A specific class of Amplified Piezo Actuators, so called APA has been patented, developed and qualified. Their applications concern subjects as various as Scientific Instruments for Space payloads (Telescopes, Microscopes), Micro-Satellites Propulsion Valves or Active flaps of Helicopter Blades.

Control of magnetic actuators in electric contactors by current shapping

19 June 2023

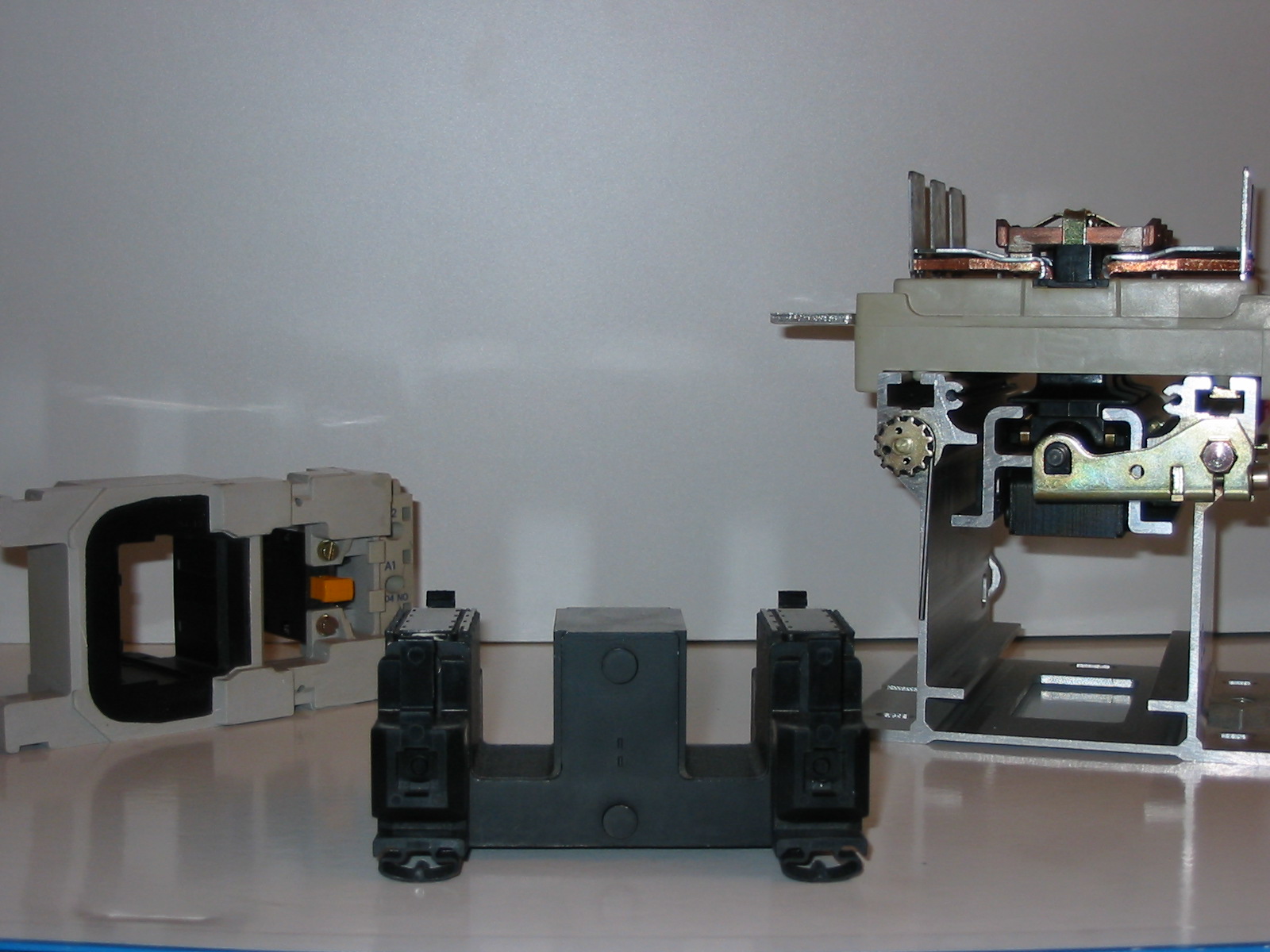

Most of present electric contactors use magnetic actuators of reluctant type (so called electromagnets) that are supplied with a simple voltage source. The use of a reluctant actuator in this condition leads to a considerable force increase when the magnetic circuit is closing, which creates damaging rebounds of the electrical contacts. To have a better control of the closing dynamics, we develop an electric drive method to reduce impact speed and to improve the closing dynamics. In this method, the reluctant actuator structure is unchanged. The appropriate current shape to be injected into the actuator is determined using a calculation method.

Force Stepping Piezo Actuator : a motorised solution for high resolution positioning and external forces resistance

19 June 2023

Typical holding force of piezo motors is defined by friction force, required to make motor move. However, increase of friction force is not inconsequent for motor performances in terms of speed, max motion force and lifetime (tribology). In this paper, a new motor, offering high resolution positioning and holding position when unpowered, is presented. Based on a Stepping Piezo Actuator [1] at its core, this new design decouples the outer forces from the most sensitive parts of the motor. This allows the motor to propose a high force/mass ratio and sustain even higher forces without supply. Results obtained on prototype are presented, giving the reader the benefits of proposed technology.