Cedrat Technologies products applied to machining processes

Laser machining processes are experiencing rapid growth, driven by increasing demands for productivity, quality, and flexibility in sectors such as automotive, aerospace, medical, watchmaking, jewelry, and electronics.

Fast Steering Mirrors (FSM) developed by CTEC represent a major advance for manufacturers of welding, cutting, drilling, and laser marking machines seeking to offer compact, dynamic, and precise solutions to their end customers.

A key technology for modern laser production

FSMs perform dynamic beam shaping (DBS) and enable the laser beam to be directed at very high speed and with micrometric precision, without moving the laser head or the workpiece. By incorporating rapid oscillatory movement of the beam (known as wobbling), they offer the possibility of:

• Precisely control the laser trajectory for complex geometries.

• Improve machining quality (welding quality, drilling, etc.).

• Distribute heat optimally to avoid overheating areas.

• Artificially increase the beam size.

Unique competitive advantages

Compared to traditional systems such as galvo scanners, CTEC’s FSMs stand out for:

• Unmatched compactness (8 times smaller than current systems),

• Fast dynamics thanks to piezoelectric actuation (>1 kHz),

• Virtually unlimited service life thanks to the absence of friction parts,

• Sub-micrometric precision suitable for the most demanding applications

With a single mirror and up to 3 degrees of freedom (tip, tilt, and piston depending on options), FSM technology reduces bulk, improves reliability, and lowers maintenance costs while offering greater control flexibility than existing proprietary solutions.

Compared to piezoelectric FSMs on the market, CTEC’s FSMs stand out thanks to their ability to withstand laser flows of several tens of kilowatts and a cooling system that enables continuous use over an angular range of several tens of milliradians at speeds of several kilohertz.

Targeted applications and markets

FSM are aimed at laser machine manufacturers and their end customers in strategic sectors:

Vacuum laser welding

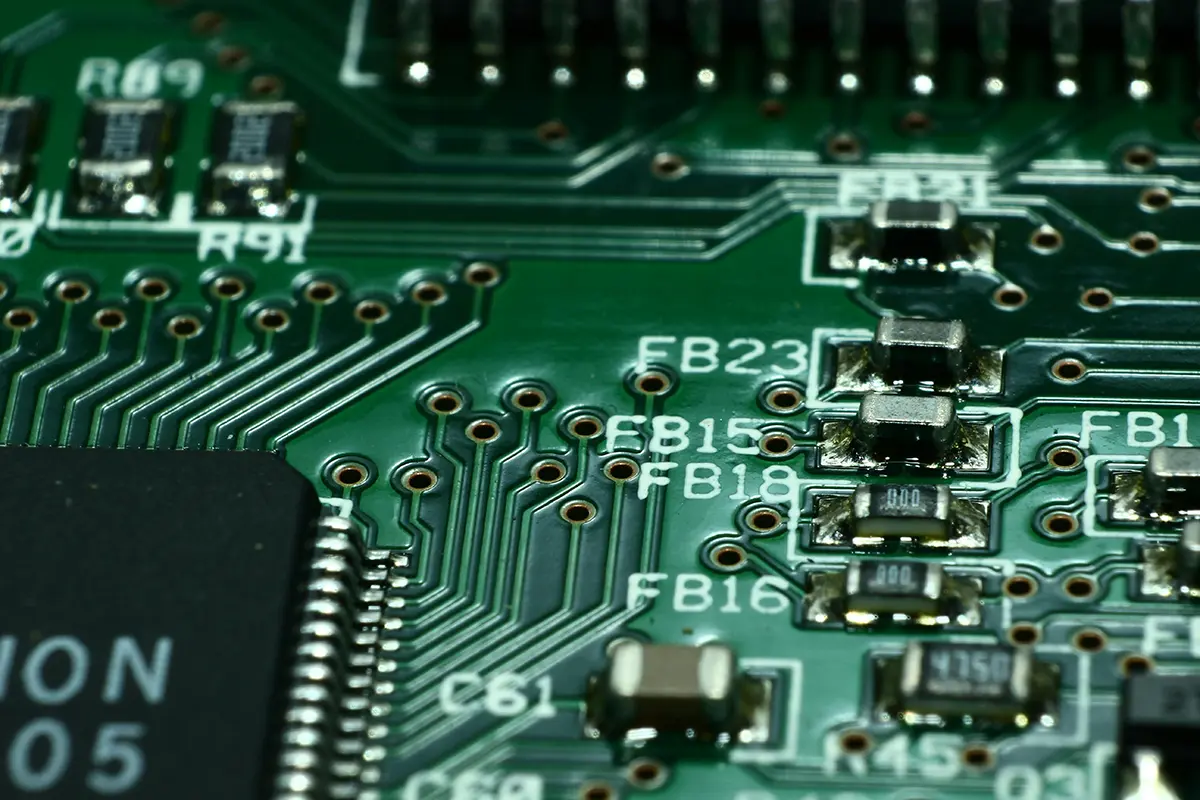

A premium quality technique for watchmaking, jewelry, and cutting-edge electronics.

Laser cutting and micro-drilling

A process combining speed and precision for the aerospace and automotive industries.

Additive manufacturing

Achieve better material fusion and fewer defects.

Industrial marking

CTEC systems enable flexibility and customization of high-speed patterns.

Projects such as LASERWAY have already validated the potential of this technology through demonstrators, with measurable gains in productivity and quality.

Outlook and roadmap

The first FSM demonstrators have reached TRL4-5, with performance superior to competing systems. The goal is to reach TRL7 for commercialization as early as 2026, supported by industrial partners and premium prospects.

With its recent patents, expertise in piezoelectric and magnetic actuation, and opto-mechanical know-how, CTEC is positioning itself as a key player in equipping the next generation of high-performance laser machines.

Need an expert for your project?