Production Machine

Has already demonstrated that mechatronic solutions create high added value in manufacturing processes while being cost effective. Our customers are advanced machine manufacturers, machine-tool builders, tool makers, spindle suppliers and end users willing to optimize advanced metal cutting, metal forming, extrusion and chemical processes.

Our mechatronics components such as actuators, sensors, drivers and controllers, are specifically designed for manufacturing environments. They are extra flat, powerful and precise and are traditionally used in harsh, heavy duty and high temperature environments. In addition the motional and sensing performances cover a wide dynamic bandwidth.

Starting from diagnostic services, mechatronic systems are designed to be Plug & Play Products or integrated as OEM versions in new machines. The scope of our solutions is not limited to engineering work. They offer the opportunity of large-scale industrial cost-effective products. The projects of today are the smart products of tomorrow.

VIBRATION ASSISTANCE

| Operation – Process | Solution | Benefit |

|---|---|---|

| Laminated carbon / titanium drilling 6 axis robot unit | Vibrating tool holder Plug & Play via HSK 32 | Improves hole quality 30% time saving per cycle |

| Multiple-hole drilling Electrical discharge machining | OEM motion solution Embedded into the EDM head | Overall cycle time reduced by 30% Stabilization of the process |

| White goods forming Deep drawing / stamping process | OEM friction control unit Embedded into the tool and die | No crack formation on sheet metal Reduce down-time and reject rates |

| Hard-to-machine material Turning process | Chip / swarf breaker Plug & Play via DIN 69880 | Controlled chips / swarfs length No interrupted production |

| Hard and brittle material Milling, grinding, turning and drilling | Ultrasonic or high frequency tool Plug & Play attachment tool | Improves glass cutting quality Faster machining of hard material (+10%) Tool life increased on diamond tool (+20%) |

| Sono-chemistry Antibacterial treatment of textiles | Innovative Ultrasonic transducer Tank unit | Product life time (+200%) |

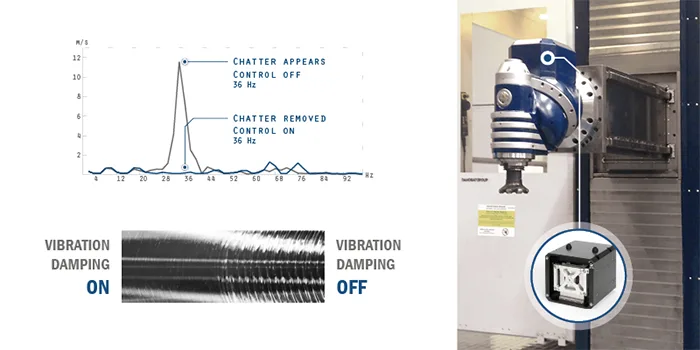

VIBRATION DAMPING

Milling, turning, grinding and drilling processes are limited by chatter vibrations related to the flexibility of the machine tool structure. Such vibrations reduce cutting speeds to well below the capacities of machines or tools. They also result in noise, poorfinish, unacceptable tolerances and sometimes tool breakage.

Parasitic vibrations are removed by installing intelligent damper units on existing or new machines. Our solution can be supplied in a Plug & Play format for immediate effect or fully integrated.Typical chatter vibration reductions over [1Hz-1kHz] are [-10dB;-20dB]. Improved stability of the process is observed in all cases.

| Operation – Process | Solution | Benefit |

|---|---|---|

| Heavy roughing operations. Milling machine | Active damping Solution Embedded into spindle head | Cutting capability is doubled Improved stability is observed |

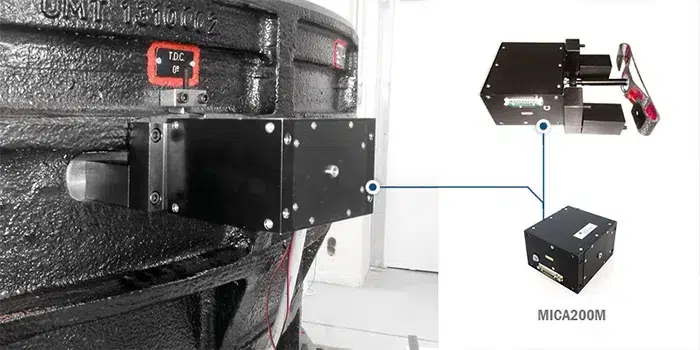

| Longitudinal turning steel slender bar Lathe machine | Semi active work-holding device Active Plug & Play tool holder | Reliability is improved +20% higher feed rates |

FAST & PRECISE POSITIONING

Long and slender parts are distorted during machining. Cutting and forming conditions may also vary during the machining process without being observed and controlled. An additional cutting axis may be necessary to produce complex parts. These distortions lead to inacceptable inaccuracies and decreaseprocess flexibility.

The solution passes through a sensory and active fixture system which detects distortion and controls active repositioning of the clamp achieving the desired part geometry and tight tolerances.

| Operation – Process | Solution | Benefit |

|---|---|---|

| Oval or aspherical machining Synchronized with Lathe rotation | Long stroke servo tool Lathe turret interface | Fast machining of optics High quality oval piston manufacturing |

| Accurate finishing Milling, grinding, turning | XY piezo stage Embedded into the clamping fixture | Precise finishing Machine resolution improved: 10nm |

| Accurate finishing Milling, grinding, turning | Force sensor Embedded into the work-holder Plug & Play via standard tool holder | Precise cutting force Improves multilayer cutting quality |

| Long and slender part machining Milling, grinding, turning | Active clamping fixture | Tighter tolerance achieved |